Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

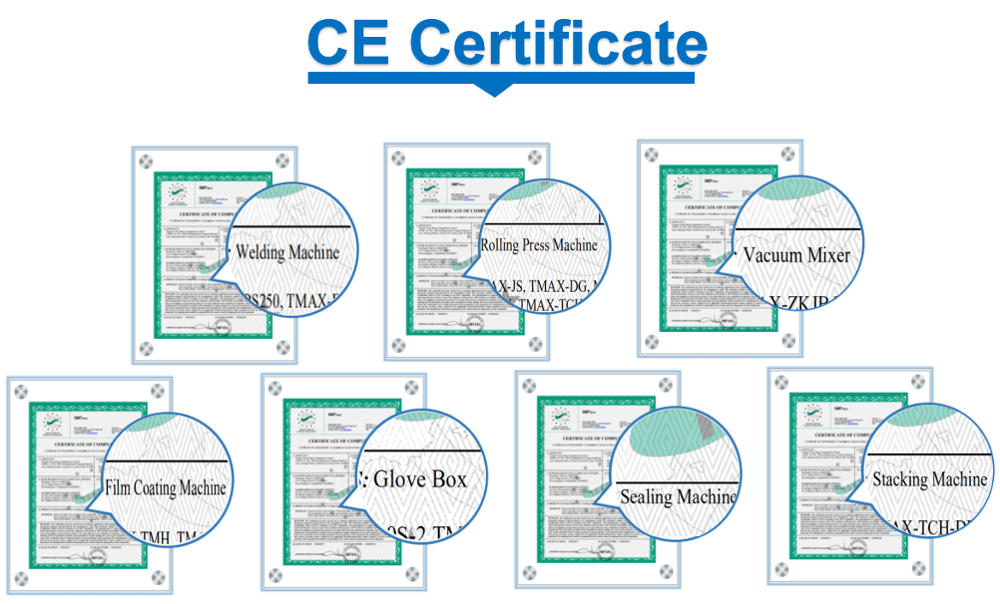

TMAX-KT-SD150Certificate:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportAutomatic High-precision Vertical Slit Coating Equipment with Air Knife

Product characteristics

Slit coating device is a high-precision vertical coating equipment, which can control the liquid supply and coating speed, high control accuracy, with the wind knife assisted film forming function, can obtain accurate and uniform film, which is used in the advanced manufacturing and research and development fields of perovskite solar cell film preparation, OLED/QLED, fuel cell and other industries.

Technical parameter

|

1. Basic parameters of the substrate |

|

|

Name |

Flexible conductive PET/PEN, conductive FTO/ITO, etc |

|

Thickness |

1-5mm |

|

Coating size |

150mm*150mm Coating width 50-150mm compatible (determined by gasket) |

|

2. Film parameters |

|

|

Solution viscosity |

<1-100cps |

|

Wet film thickness |

1-100μm |

|

Dry film thickness |

Dry film 50-10000nm |

|

3. Basic parameters of the device |

|

|

Equipment table |

Heating table (up to 150℃, temperature control accuracy ±1℃), temperature uniformity ±1℃, platform flatness ±10μm (non-heated, there will be deformation after heating) |

|

Feed liquid |

High precision liquid pump (0.1-2000ul/s) for liquid supply |

|

Coating speed |

0-100mm/s, freely choose the coating speed, the program sets the speed of the segment |

|

Control system |

Siemens PLC control system |

|

Horizontal control system |

Four-point leveling structure |

|

Repeatability |

±0.01mm |

|

Power source |

220V,2.5Kw |

|

4. Die parameters |

|

|

Coating head machining accuracy |

Die head flatness/straightness ≤1.5μm |

|

Maximum width of coating head |

150mm |

|

Die head cavity volume |

About 2mL |

|

Coating head material |

Germany imported stainless steel 17-4, corrosion resistance and stability is good, the use of high-precision precision machine tools imported from Japan, constant temperature workshop processing and production. |

|

5. Device working environment |

|

|

Operating environment Temperature (℃) |

25℃±2℃ |

|

Relative humidity |

<70%, no condensation |

|

Pollution level |

Level 2, should not be installed in dusty, corrosive gas places |

|

6. Configure the device |

|

|

Air knife |

Adjustable height and angle, three-sided air intake, high air uniformity |

|

Controls |

Servo motor |

|

Gasket |

Different thickness, width of the gasket |

|

Dimension |

650*450*730mm (reference size) |

|

Weight |

80Kg |

Coating advantage

1. Large area continuous uniform film formation;

2. Automatic liquid supply, automatic cleaning;

3. Air knife/heating platform, in-situ film formation;

4. Save solution, save more than 90% than spinning coating solution;

5. Product yield of more than 95%;

6. Wide range of applications, perovskite batteries, OLED, fuel cells and other fields.

Previous :

High Speed Laser Etching Machine for Solar Cell Fabrication LineNext :

Perovskite Films Machine or Vertical Slit Coating Device with High Precision Coating HeadCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported