Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

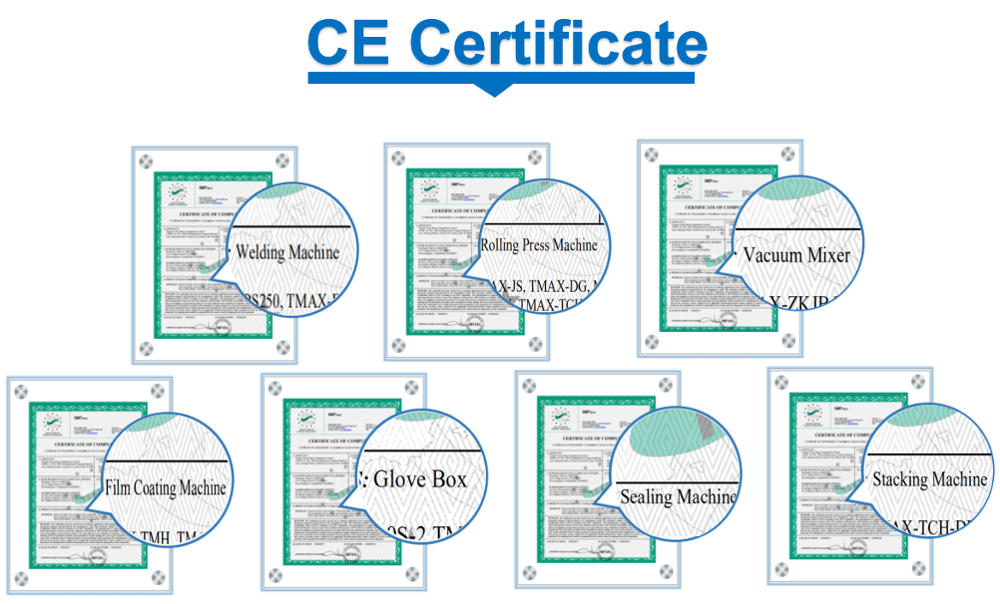

TMAX-KT-Z150Certificate:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportLab 100mm or 150mm Film Width Automatic Scraping Coating Instrument for Perovskite Films

Specially developed for the laboratory, a high-precision vertical coating equipment has the characteristics of fast preparation speed, film formation and good uniformity, especially suitable for the preparation of 5-20cm perovskite battery modules in the laboratory, as well as the preparation of fuel cells, OLED and other devices, easy to clean, easy to save and easy to operate, good film formation and other advantages. Vacuum adsorption at the bottom heating belt, in situ film formation assisted by air knife, and high precision inlet coating head.

Technical parameter

|

Substrate thickness |

1-3mm |

|

Solution viscosity |

0.8-10000 CPS |

|

Layer thickness |

5-100μm(wet film) |

|

Coater accuracy |

5 microns |

|

Film width |

100mm/150mm(standard model) |

|

Coating speed |

1-100mm/s |

|

Heating platform |

The maximum temperature of the platform is 150℃, and the temperature uniformity is ±2℃ |

|

Power |

220V 50 Hz Maximum 2.5KW |

|

Equipment size |

Length * Width * height =550*300*380mm(for reference) |

|

Air knife |

The air discharge is uniform, and the auxiliary film forming performance is good |

|

|

|

Product characteristics

1. Coating platform: The coating platform with high levelness can be vacuum adsorbed and heated to ensure the fixing of rigid substrate and the spreading and bonding of flexible substrate, which can increase the uniformity of the film. Heating, vacuum adsorption, air knife assisted film formation.

2. Coater: High precision corrosion resistant original imported adjustable coating head (resolution up to 5um, straightness ≤1um). Made of anodized aluminum alloy, no decolorization, acid and alkali resistance, corrosion resistance, can accurately set 0-3000um thickness, and can be completely disassembled and cleaned with solvent. Necessary for paint and coatings manufacturing, and suitable for various experiments. Save the solution.

3. Coating speed: It can be adjusted stepless in the range of 0-100mm/s, and the coating length (starting point/end point) and moving speed can be adjusted arbitrarily. Speed adjustable

4. Good applicability of solution: Viscosity range of coating solution: 0.8- 10000CPS.

5. Wide range of applications: Perovskite batteries, fuel cells, lithium-ion batteries and OLED applications, but also suitable for quality control analysis, paint, paint, ink, varnish, adhesive distribution characteristics.

Previous :

355nm Wavelength Vertical Type Laser Marking Equipment with Ultraviolet LaserNext :

400X400mm Lamination Area Hot Compression Sealing Machine with Foldable Cooling Sample TableCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported