Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-PP-900LPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

15 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

One year limited warranty with lifetime technical supportLab 900C 10T Programmable Automatic High Temperature Hot Press

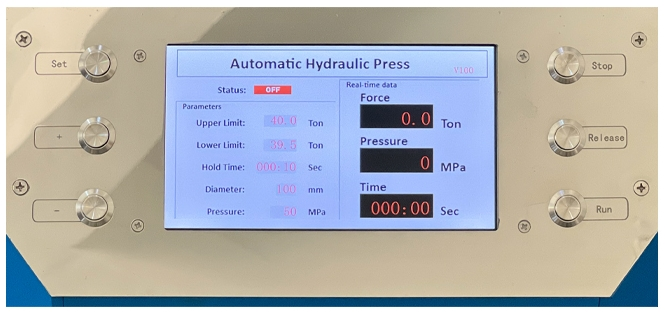

Setting interface

Settings

Under the operation interface, press the setting button to enter the setting interface, press the setting button again, move the setting content, move to the mold diameter, press the setting button again to return to the operation interface. Note: When the time is set to "0", the setting time is infinite.

+

On the operation screen, press the + key to add the number.

-

On the operation screen, press _ to reduce the number of Settings.

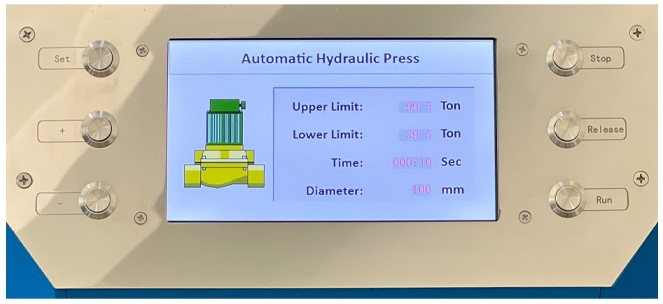

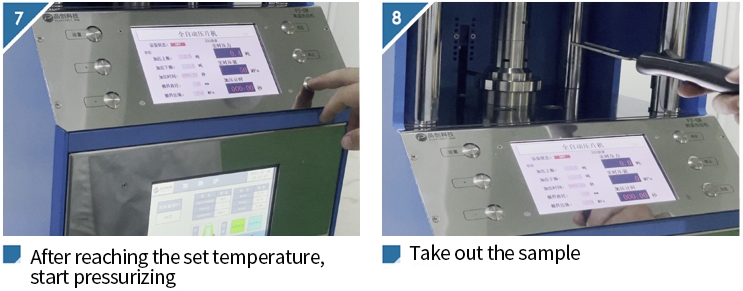

Operating interface

Stop

When the equipment is running, press the "Stop" button, the equipment will stop the motor operation, and open the pressure relief valve to release the pressure.

Release

The equipment starts running when the Release button is pressed down; when the pressure exceeds the specified value or the limit switch is pressed, the equipment stops automatically and releases pressure. The operation also can be stopped manually.

Sample

The equipment starts running when the Sample button is pressed down; when the pressure exceeds the specified value, the pressurizing stops and maintains the pressure; when the pressure is lower than the lower limit.the equipment compensates automatically, when the timing ends, the equipment releases pressure automatically.

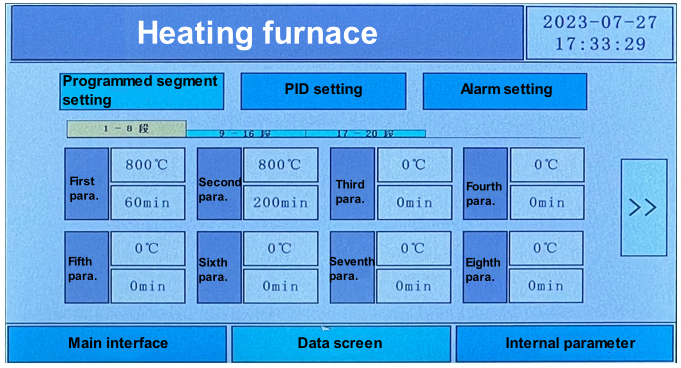

Setting interface

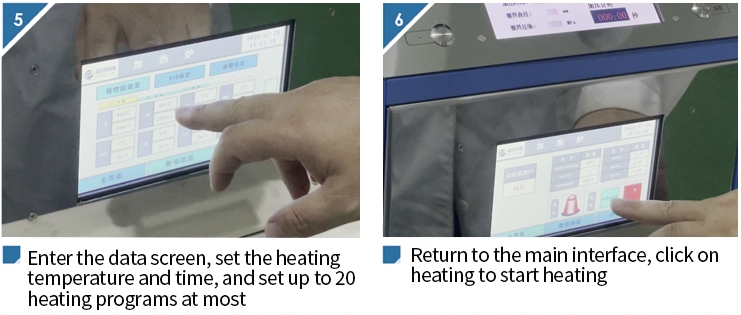

Step 1: Select the data screen and enter the Settings screen

Step 2: Select "Programmed Segment Settings"

Step 3: There are 20 temperature control procedures in the program, select the first paragraph

Step 4: According to the requirements of the experiment, set the temperature and heating speed of the first stage

Step 5: If you need multiple heating procedures, you can set up 20 procedures

Step 6: After setting, press the main screen to return to the operation screen

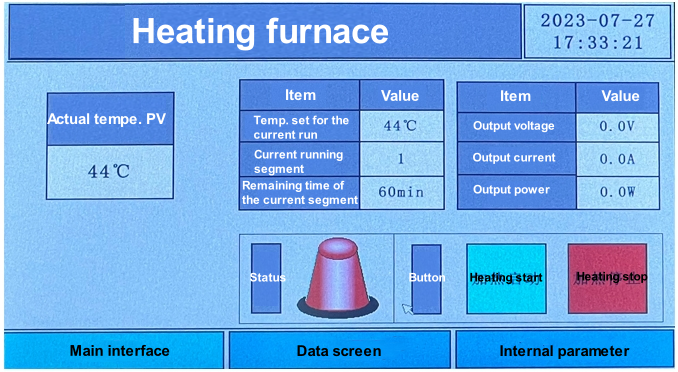

Operating interface

Step 7: On the main screen, press "Heating start"

Step 8: The device is programmed to heat up.

Step 9: Automatically stop the device after the end of heating. If the setting is wrong, for example, the set temperature is not reached within the specified time, the device will automatically terminate.

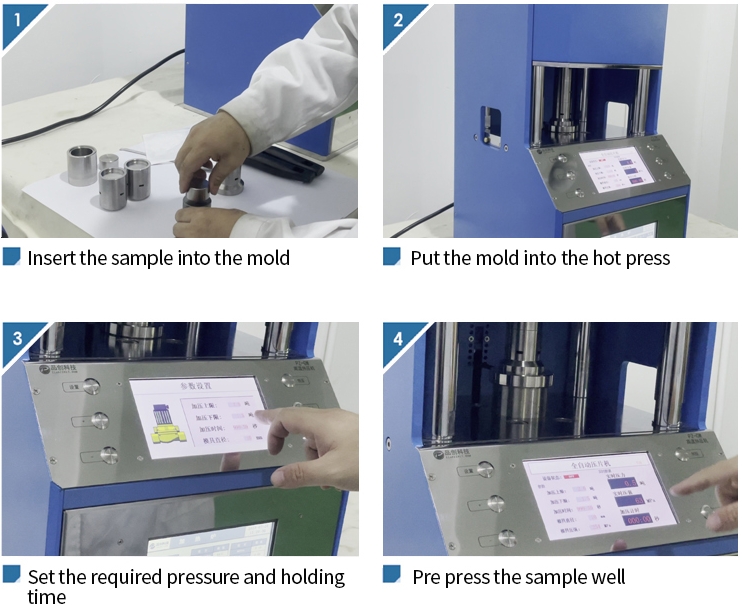

Operation procedure

Technical parameter

|

Instrument type |

PP-900L |

|

Pressure range |

0-10.0 tons |

|

Pressurization process |

Programmed pressure - programmed pressure retention - timed pressure relief |

|

Holding time |

1 s to ∞ s |

|

Cylinder stroke |

80mm |

|

Heating temperature |

Up to 1000℃ |

|

Mold material |

Nickel base alloy (high temperature resistant material) |

|

Sample size |

Ф 10-30 mm |

|

Mold contour |

Ф 50 x90mm |

|

Furnace aperture |

Ф 60 mm |

|

Overall size |

400x380x780(LxWxH) |

|

Power source |

220V 50Hz |

|

Powder press size diagram |

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

300C 40T 400*400mm Heat Plate Size Automatic Hot Press Optional Rapid Cooling Water CoolerNext :

Lab 25T Integrated Type Programmable Vacuum Tablet Press for Glove BoxCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported