Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-PP-600BPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

15 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

One year limited warranty with lifetime technical supportLab 300C or 500C Small Tonnage Automatic Hot Press

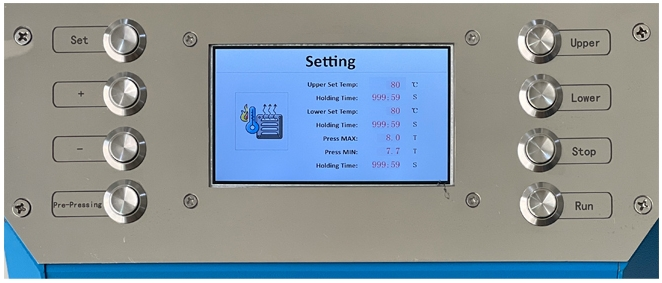

Setting interface

Settings

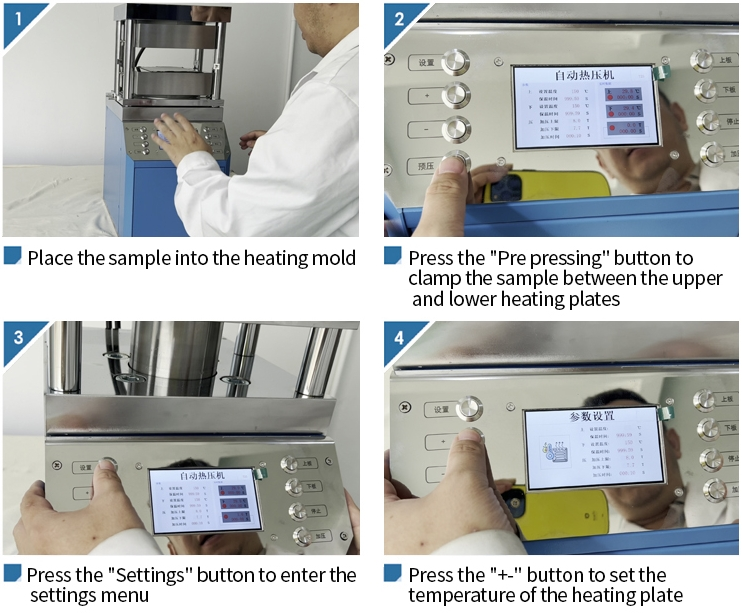

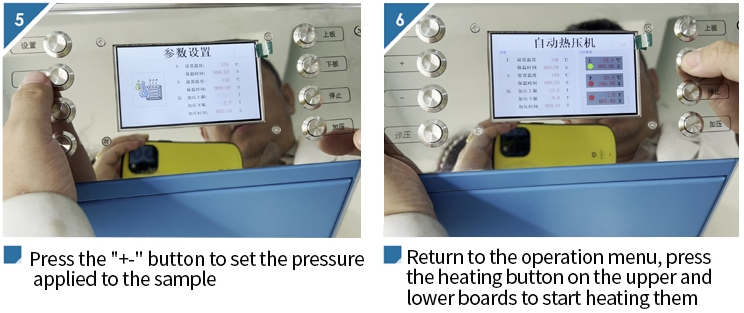

Under the operation interface, press the setting button to enter the setting interface, press the setting button again, move the setting content, move to the mold diameter, press the setting button again to return to the operation interface. Note: When the time is set to "0", the setting time is infinite.

+

On the operation screen, press the + key to add the number.

-

On the operation screen, press _ to reduce the number of Settings.

Pre-pressure

Press the Pre-pressure button to close the upper and lower heating plates.

Operating interface

Upper plate

Press the "Upper plate" button in the operation interface, and when the upper heating plate starts to heat to the set temperature, the timer starts to record the time and starts to maintain the constant temperature. When the timer is over, stop the heat. Or press the "Upper plate" button again to stop heating the upper heating plate. During the heating process, all setting buttons are invalid.

Lower plate

Press the "Lower plate" button in the operation interface, and after the lower heating plate starts to heat to the set temperature, the timer starts to record the time and starts to maintain the constant temperature. When the timer is over, stop the heat. Or press the "Lower plate" button again to stop heating the Lower heating plate. During the heating process, all setting buttons are invalid.

Stop

When the equipment is running, press the "Stop" button, the equipment will stop the motor operation, and open the pressure relief valve to release the pressure

Run

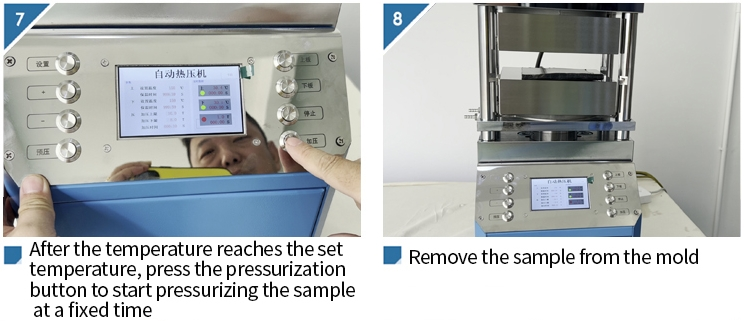

Press the "Pressurization" button, and the equipment will start. When the pressure reaches the set pressure, stop pressurization and time to maintain pressure. When it is below the lower limit of pressurization, it will automatically replenish pressure.After the timing is completed, it will automatically release pressure

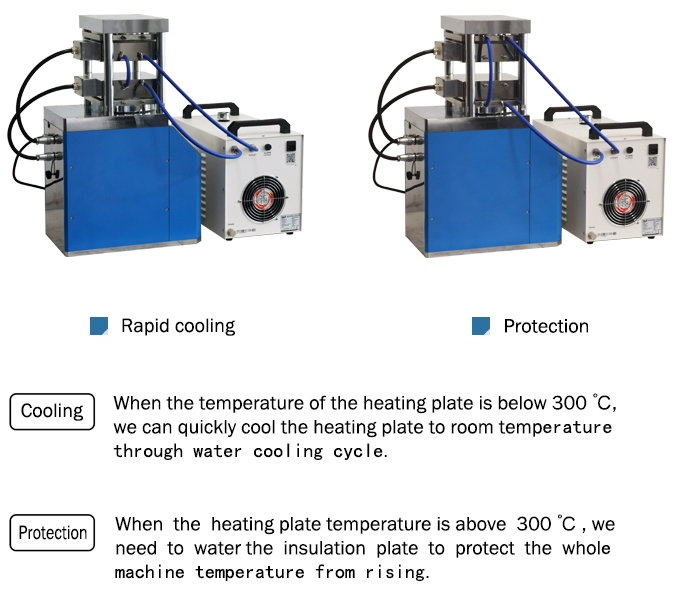

Water cooling diagram

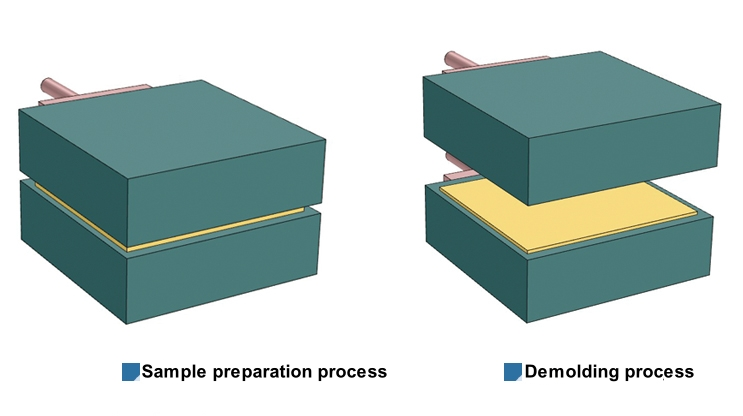

Mold operation diagram

Operation procedure

Technical parameter

|

Instrument type |

PP-600B(300.0℃)/PP-600BG(500.0℃) |

|

Pressure range |

0-5.0 tons |

|

Pressurization process |

Programmed pressure - programmed pressure retention - timed pressure relief |

|

Holding time |

1 to 0 seconds |

|

Mold heating temperature |

Room temperature -300.0℃/500.0℃ |

|

Constant temperature time |

1 s to ∞ s |

|

Temperature control accuracy |

0.1 ℃ |

|

Heat insulation method |

Inlet heat shield |

|

Cooling method |

Water cooling rapid cooling [optional water cooler] |

|

Mold size |

Double plate heating 120x120mm(MXN) with lead screw |

|

Work space |

140x140x130 mm |

|

Overall size |

182x306x500mm(LxWXH) |

|

Power source |

900 W(220V/110V can be customized) |

|

Main engine weight |

78Kg |

|

Powder tablet press size diagram |

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Lab 40T Automatic Programmable Powder Tablet PressNext :

30T Double Plate Hydraulic Hot Press Machine with Split StructureCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported