Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

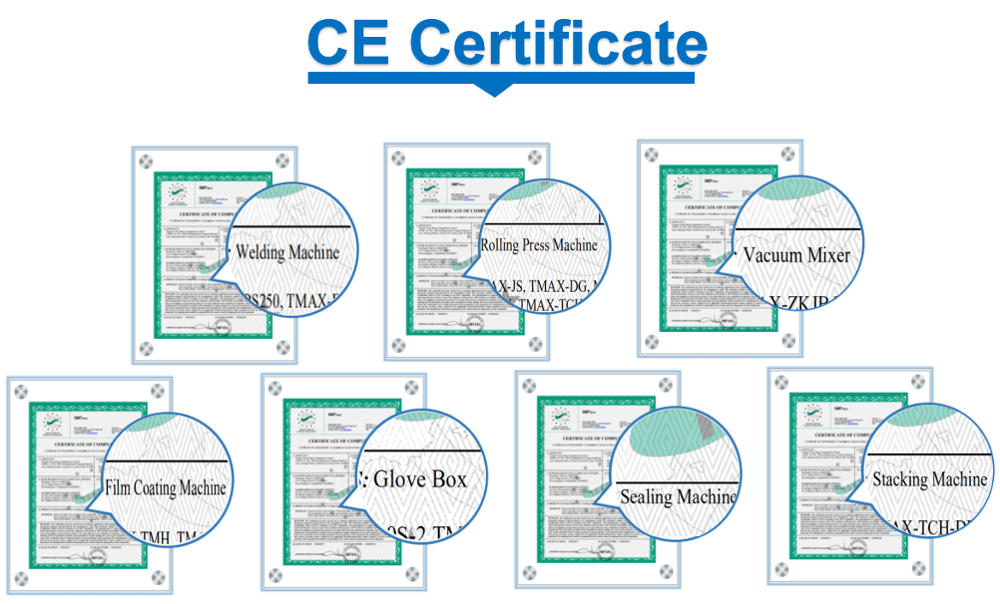

TMAX-Printing MachinCertificate:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportHigh Precision Automatic Printing Machine Optional Screen Automatic Cleaning Device

Equipment use

This machine is suitable for screen printing of solar panels, semiconductors, biological test panels, electronic components and other products.

Equipment Configuration (Optional)

1. Automatic feeding and unloading

2. Screen plate automatic cleaning

3. Doctor blade pressure, automatic adjustment of level

4. Device to divert material during discharging

5. Countertop automatic paper roll

6. Lift the plate

Specification parameters:

|

1. Basic specifications |

|

|

Specification |

Content |

|

Machine dimensions |

Length 1500× width 840× height 1620mm |

|

Printing area |

Max. 250 x 250mm/ min. 40 x 50mm |

|

Substrate thickness |

0.05 mm to 5.0mm |

|

Uniformity of film thickness |

﹤±0.001 mm |

|

Use power |

Three-phase, 220V, 50Hz 3.0KW |

|

Air pressure |

0 ~ 6kgf/cm2 PSI (Including air pressure reservoir, keep the mechanical pressure stable) |

|

2. Printing table |

|

|

Printing table size |

360mm×360mm |

|

Countertop suction area |

260×260mm |

|

Table entry and exit repetition accuracy |

0.001mm (Servo + ball screw) |

|

Table feed/send direction |

Left and right |

|

Printing table adjustment |

X: ±4mm, Y: ±4mm, θ : ±2° |

|

Table alignment accuracy |

﹤±0.002mm |

|

Repeat printing accuracy |

﹤±0.005mm |

|

Mesa plane accuracy |

﹤±0.015mm |

|

Parallelism between table and doctor blade |

﹤±0.02mm |

|

The parallelism between the table and the frame clip |

﹤±0.02mm |

|

Table access velocity |

10 ~ 1500mm/s (Adjustable) |

|

Maximum lift stroke of platform |

15mm |

|

Platform drive |

Servo motor + linear slide + ball screw (to ensure low speed movement without inching phenomenon) |

|

Mesa material |

Configure according to customer requirements |

|

Automatic paper rolling function |

(Optional) |

|

Automatic alignment device |

CCD automatic positioning |

|

Automatic supply and storage |

Automatic (According to customer demand) |

|

3. Printing base |

|

|

Printing mode |

Printing base fixation |

|

Printing speed |

0 ~ 1200mm (Per second) |

|

Printing pressure |

0 ~ 20kg/cm² |

|

Scratch stroke |

0 ~ 300mm (Digital setting) |

|

Printing motor |

Stroke setting |

|

Doctor blade height adjustment |

20mm |

|

Doctor blade angle |

-30° To 30° |

|

Reink knife height adjustment |

20mm |

|

Return ink knife Angle |

-30° To 30° |

|

Adjust the level on both sides of the doctor blade |

Have |

|

Printing drive |

Servomotor |

|

4. Frame seat |

|

|

Maximum size of the mesh frame |

550×550mm |

|

Frame thickness |

25 ~ 50mm |

|

Screen fixing |

4 point cylinder lock plate |

|

Screen stand |

Immobilization |

|

Gap between screen and desktop |

0 to 15mm |

|

Screen automatic cleaning |

(Optional) |

Previous :

Manual or Automatic Glue Dispenser Machine for The Fabrication of Perovskite Solar CellNext :

Nano Nickel Oxide Powder Suitable for Perovskite Solar CellCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported