Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-BSW07S-10TPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

15 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

One year limited warranty with lifetime technical support40T CNC Automatic Servo Hydraulic Oil Press Machine for Powder Forming

Introduction

The servo hydraulic press is a new type of energy-saving and high-efficiency hydraulic press that uses a servo motor to drive the main drive oil pump to reduce the control valve circuit and control the hydraulic press slider head.

The servo hydraulic press is a smart press that has been newly designed by Bussie Machinery R&D personnel through computer-aided design technology combined with years of design and development experience.

Product parameters

|

Model |

BSW07S -10T |

BSW07S -20T |

BSW07S -30T |

BSW07S -40T |

BSW07S -50T |

BSW07S -60T |

|

|

Nominal pressure(T) |

10 |

20 |

30 |

40 |

50 |

60 |

|

|

Maximum working pressure of liquid(Mpa) |

21 |

21 |

21 |

21 |

21 |

21 |

|

|

Surface height(E) mm |

850 |

850 |

850 |

850 |

850 |

850 |

|

|

Maximum opening distance(H)mm |

500 |

500 |

500 |

550 |

550 |

600 |

|

|

Deep throat(s) mm |

200 |

200 |

225 |

225 |

250 |

250 |

|

|

mm Maximum stroke |

300 |

300 |

300 |

300 |

300 |

400 |

|

|

Work bench size

|

Left and right(L) mm |

500 |

500 |

550 |

550 |

650 |

650 |

|

Before and after(W) mm |

400 |

400 |

450 |

450 |

500 |

500 |

|

|

Speed |

Rated load speed (mm/s) |

165 |

165 |

165 |

165 |

155 |

155 |

|

Working speed(mm/s) |

3-25 |

3-25 |

3-25 |

3-18 |

3-15 |

3-15 |

|

|

Return speed(mm/s) |

140 |

140 |

140 |

125 |

125 |

125 |

|

|

Main frame size(mm) |

700x950x2160 |

750x1000x2250 |

760x1000x2300 |

780x1050x2350 |

800x1060x2500 |

830x1100x2600 |

|

|

Power(Kw) |

3.7 Kw |

3.7 Kw |

5.5Kw |

7.5 Kw |

7.5 Kw |

11 Kw |

|

Features

1. This series of hydraulic presses is powered by 2-20MPA hydraulic pressure, with external three-phase AC380V 50HZ or three-phase AC220 60HZ AC power supply.

2. Energy saving: hydraulic and electric control adopt intelligent servo energy saving system, saving 30%-60% compared with traditional hydraulic machine.

3. Safety and precision: Each machine is equipped with infrared safety grating to effectively protect the operator and servo CNC precision control to ensure the repeatability of the machine can reach ±0.03mm and the pressure error is ±1%.

4. Low failure rate: servo control system, no useless work, oil temperature is not easy to rise, and there is no negative pressure in the oil circuit system, which greatly reduces the fault and prolongs the service life of the hydraulic components. Key reset function.

5. Stable and durable: the frame adopts the whole frame structure, the slider adopts the precision guide rail to run, the shock resistance and the anti-side pressure are strong, the whole machine is stable, precise and durable, suitable for precision press fitting, assembly, blanking, forming and extrusion. And many other process uses.

6. Convenient maintenance: The whole machine is designed according to different function modes and designed into a module structure. It is easy to disassemble and assemble. The general fault can be directly viewed through the touch screen, and the maintenance is simple.

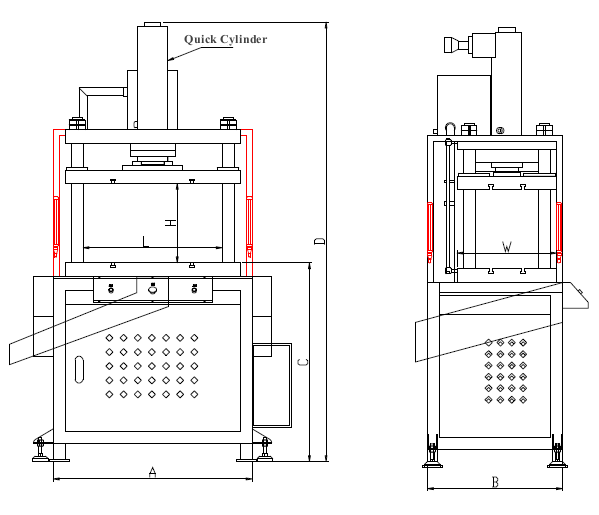

Dimension

Application

Pictures

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Small Double Action Servo Hydraulic Press Machine Metal Sheet Forming Machine for Multiple Materials MoldingNext :

50T Single Column Metal Deep Draw Hydraulic Press Machine for Punching Ceramic PowderCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported