Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-BSW06K-10TPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

15 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

One year limited warranty with lifetime technical support4 Column Servo CNC Hydraulic Press for Alumina Ceramic Powder Molding

Introduction

Fast hydraulic press appling four-post three plate structure, the middle plate for activities, on both sides of the guide pin connected by chrome plated rod up and down worktable, on both sides of the plate is made of linear bearing guide pin to guide, can effectively guarantee the activities on the working plate and the lower the parallelism and perpendicularity, activity board parallelism can reach 0.1 mm above or below, the machine adopts the advanced dual cylinder, whether noise speed electricity power, is superior to the ordinary hydraulic press, hydraulic press is a high efficiency of a new generation of environmental protection.

Product parameters

|

Model |

BSW06K -10T |

BSW06K -20T |

BSW06K -30T |

BSW06K -40T |

BSW06K -50T |

BSW06K -60T |

|

|

Nominal pressure(T) |

10 |

20 |

30 |

40 |

50 |

60 |

|

|

Maximum working pressure of liquid(Mpa) |

21 |

21 |

21 |

21 |

21 |

21 |

|

|

Surface height(E) mm |

850 |

850 |

850 |

850 |

850 |

850 |

|

|

Maximum opening distance(H)mm |

400 |

400 |

500 |

550 |

600 |

600 |

|

|

Maximum stroke(mm) |

300 |

300 |

300 |

300 |

400 |

400 |

|

|

Work bench size

|

Left and right(L) mm |

500 |

500 |

550 |

550 |

650 |

650 |

|

Before and after(W) mm |

400 |

400 |

450 |

450 |

500 |

500 |

|

|

Speed |

Rated load speed(mm/s) |

165 |

165 |

165 |

165 |

155 |

155 |

|

Working speed(mm/s) |

24 |

24 |

24 |

18 |

15 |

15 |

|

|

Return speed(mm/s) |

140 |

140 |

140 |

125 |

125 |

125 |

|

|

Main frame size(mm) |

850x950x2130 |

850x950x2280 |

900x1000x2300 |

900x1000x2360 |

1000x1100x2500 |

1000x1100x2550 |

|

|

Power (Kw) |

2.2Kw |

3.7 Kw |

3.7Kw |

3.7 Kw |

5.5 Kw |

5.5 Kw |

|

Features

1. Adopting four-column and three-plate structure, the vertical precision of the movable plate is controlled by four precision guide sleeves, and the parallel precision between the lower working surface and the upper working surface is less than 0.1MM.

2. This series of hydraulic presses use 2-20MPA liquid pressure as the power source, external three-phase AC380V 50HZ or two-phase AC220 60HZ AC power supply.

3. This series of equipment uses liquid as the medium to transfer energy, high efficiency, fast cutting speed, low noise, noise of equipment does not exceed 75 decibels when standby.

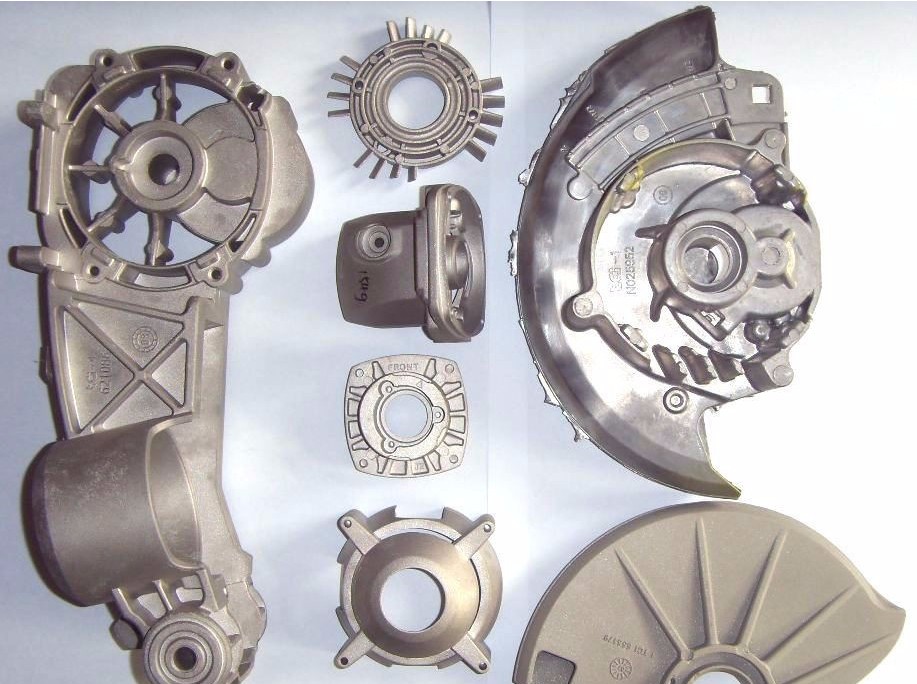

4. The punching machine has a waste blowing assembly and a waste blanking trough in the center of the lower workbench (generally suitable for cutting in the die casting industry).

5. With automatic counting function, it can be divided into manual and semi-automatic control modes. Manually, the press-fit upper mold can be stopped in any stroke range. It is equipped with an emergency rebound button, and can also be equipped with an infrared hand guard device.

6. Pressure, stroke, cutting speed, blowing time, closing height can be adjusted by the customer to facilitate operation;

7. The hydraulic system has a built-in bottom of the fuel tank, and the appearance is neat and stable. The caster and the foot cup are installed under the workbench, which can be moved lightly.

8. The hydraulic mechanical output range of this series is 10tf-100tf. Optional. (1tf=1000kgf=9.8KN).

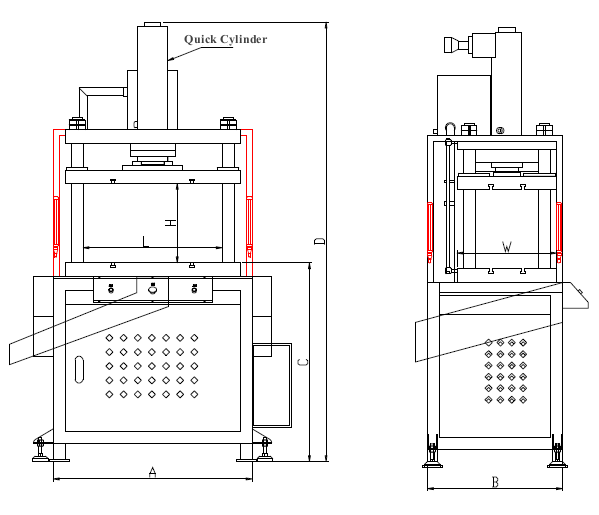

Dimension

Application

Pictures

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Categories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported