Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

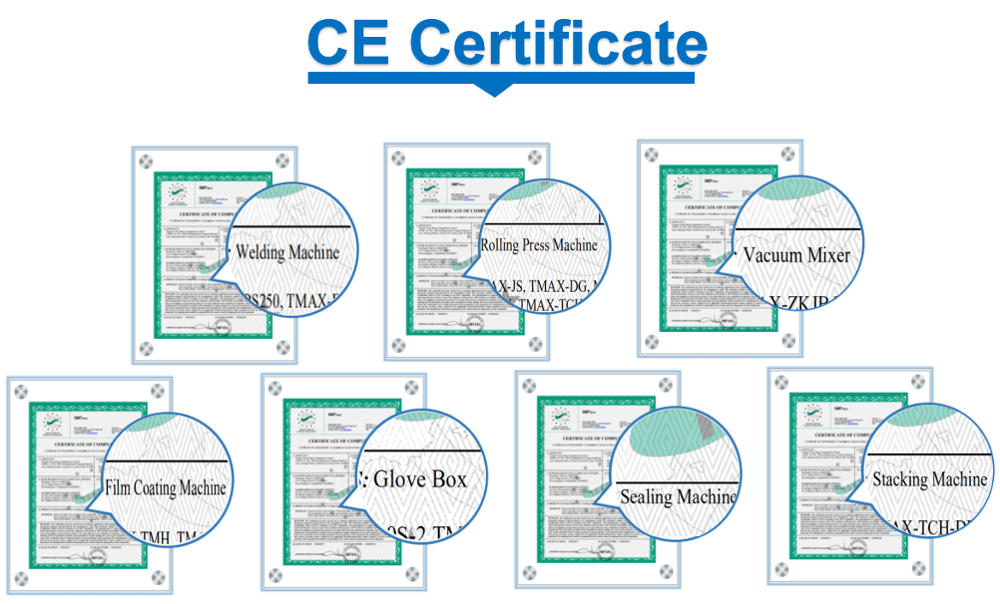

TMAX-MBMCertificate:

CE CertifiedWarranty:

1 Year limited warranty with lifetime support3L 20L And 500L Lab High-efficiency Electric Lifting And Stirring Mill for Perovskite Solar Cells

Working Principle:

The spindle driven the agitator do high speed rotating, make the grinding medium to do irregular movement.

The grinding medium would be collided, extruded, friction and sheared because of the disorderly movement,

so pulverized, finely grounded the material. Further, if the size, shape and ratio of the grinding media is different,

the grinding effect would also different . Under normal circumstances, the greater the specifications of the grinding medium,

the more coarse material crushing; Conversely, the smaller the grinding media, the finer the grinding materials. The abrasive

effective would be better with appropriate ratio of different grinding media’s specifications, coupled with the appropriately

adjusting for speed.

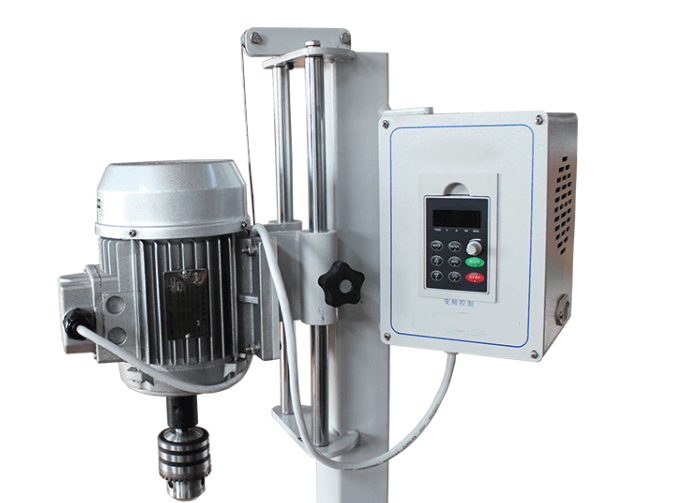

Product Features:

1.High energy utilization, and can get a very high power density, so saving energy;

2.Product size is easy to be adjusted,ensure the final degree of fineness by adjusting the residence time of material in the barrel;

3.Small vibration, low noise;

4.Simple structure, easy to operate;

5.It can achieve various of process parameters requirement, product continuously or intermittently according to the need;

6. It can be well controlled grinding temperature because the milling cylinder has a jacket;

7. Can produce devices with a variety of special features according to the need, such as: the timer, speed control mode, circulation method, temperature regulator etc;

8. Can select grinding cylinder with different materials (stainless steel, corundum ceramics, polyurethanes, zirconium, etc.) and stirring device.

The electric lifting and stirring ball mill is mainly composed of a stationary grinding cylinder filled with small diameter grinding medium, a stirring device and other auxiliary devices (such as circulation device, cooling device, timing, speed control, etc.), with high grinding efficiency and small grinding particle size, which can well meet the requirements of various process parameters, simulate various indicators in production, and at the same time, because of its small batch, low power consumption and low price Its advantages are that school, research unit and company are the first choice equipment for grinding technology, new materials and coating research. It is widely used in the production of zirconium silicate, zirconium, alumina, ceramics, chemical industry, electronic materials, magnetic materials, paper-making, coatings, non-metallic minerals, new materials, paints, graphite, calcium carbonate, pharmaceutical and other ultra-fine powders. We are committed to providing premium laboratory mixer for you!

Specification

|

|

Experimental mini type |

Experimental light type |

Production configuration |

|

Volume (L) |

0.5~3 |

5~20 |

30~500 |

|

Jar Material |

Stainless steel,

ceramic,corundum,

zirconia,polyurethane etc. |

Stainless steel,

ceramic,corundum,

zirconia,polyurethane etc. |

Stainless steel,

ceramic,corundum,

zirconia,polyurethane etc. |

|

Feed size |

Less than 5mm |

Less than 20mm |

Less than 20mm |

|

Discharging size |

Less than 1um |

Less than 1um |

Less than 1um |

|

Rotate speed (r/min) |

1400,2800 and adjustable |

50~500 |

50~500 |

|

Speed adjustment mode |

Electronic speed control |

Fixed speed or frequency control |

Fixed speed or frequency control |

|

Power |

120~550W |

1000~5500W |

1000~7500W |

Applications

Previous :

Lab Small 5L 400C Magnetic Stirrer with Integrated Heating and Speed Display Function for Perovskite Solar Cell Research EquipmentNext :

Manual Type Vacuum Spin Coater with Plate Holder Suitable for 4 Inches Substrate Used with Perovskite Solar Cell Research MachineCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported