Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-SK2-5-18TPC3Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical supportLab High Temperature 1800C 0.001Mbar Vacuum Tube Electric Furnace with Water Cooler

The picture is just for reference

|

Main parameter |

PN: SK2-5-18TPC3 Max.Temp: 1800C Working temperature:0-1700C Tube diameter:80mm Tube heating zone length:350mm Tube material:Alumina tube Heating rate:0~5 Degree/Min Max.vacuum:0.001mbar Heating element:Mosi2 heating element Thermocouple:B type Temperature accuracy: ±1℃ Voltage: 220V single phase 50hz Power: 5.5kw |

|

Inlet gas/Atmosphere |

It can be filled with various protective or destructive gases,Inert gases, mixed gases, nitrogen, oxygen, etc |

|

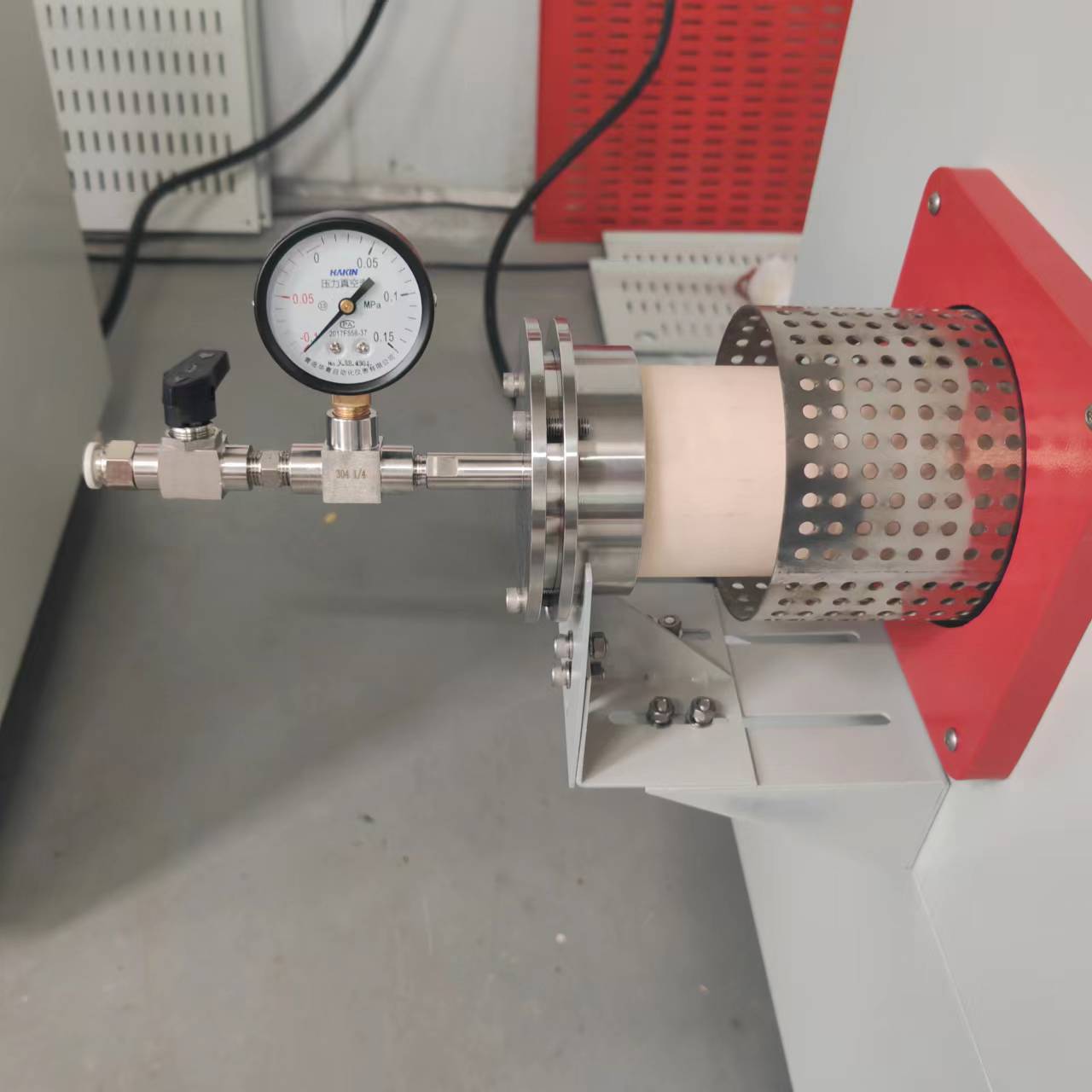

Gas control |

The air inlet can be set up 1 or more air intakes, each air inlet is provided with a ball valve, connected with a vacuum gauge. The air outlet is connected with one air outlet, and all holes are equipped with ball valves. Equipped with a vacuum pump. |

|

Appearance design |

The electric furnace adopts humanized design, beautiful and easy to operate, and the outer layer of paint is sprayed with high temperature baking technology. High temperature resistance, oxidation resistance, acid and alkali resistance.Color selection is aging resistant tone, will not cause the appearance color fade due to a long time of use. |

|

Furnace chamber material |

Adopt the advanced light alumina ceramic fiber in the world, with excellent thermal insulation effect, light weight, high temperature resistance, no crack, no crystallization, no slag, do not worry about pollution of the fired products. The energy saving effect is 60-80% of the old electric furnace. |

|

Furnace chamber design |

Furnace adopts the stepped assembly structure, integrating the mechanical law, effectively ensure the furnace in the heating process of uniform force, ensure that the heat is not easy to disperse, prolong the service life of the furnace. |

|

Furnace shell structure |

Electric furnace shell adopts double layer forced air cooling structure, so that the electric furnace works at the highest temperature and the external temperature of the shell is close to room temperature, so as to avoid accidental injury. |

|

Sealing way |

Adopt 304 stainless steel flange, with easy loading and unloading, oxidation resistance, acid and alkali resistance, double seal, ensure the sealing |

|

Temperature controlling |

Adopt international advanced touch screen temperature controller, with 30 programs with PID self-tuning, automatic temperature rise, automatic temperature drop, no duty. Temperature accuracy: ±1℃ |

|

Temperature control security |

The electric furnace adopts integrated circuit, module control, double circuit protection (partial temperature protection, ultra-high temperature protection, coupling protection, overcurrent protection, overpressure protection and other protection functions) to make the electric furnace work stable and reliable, safe. |

|

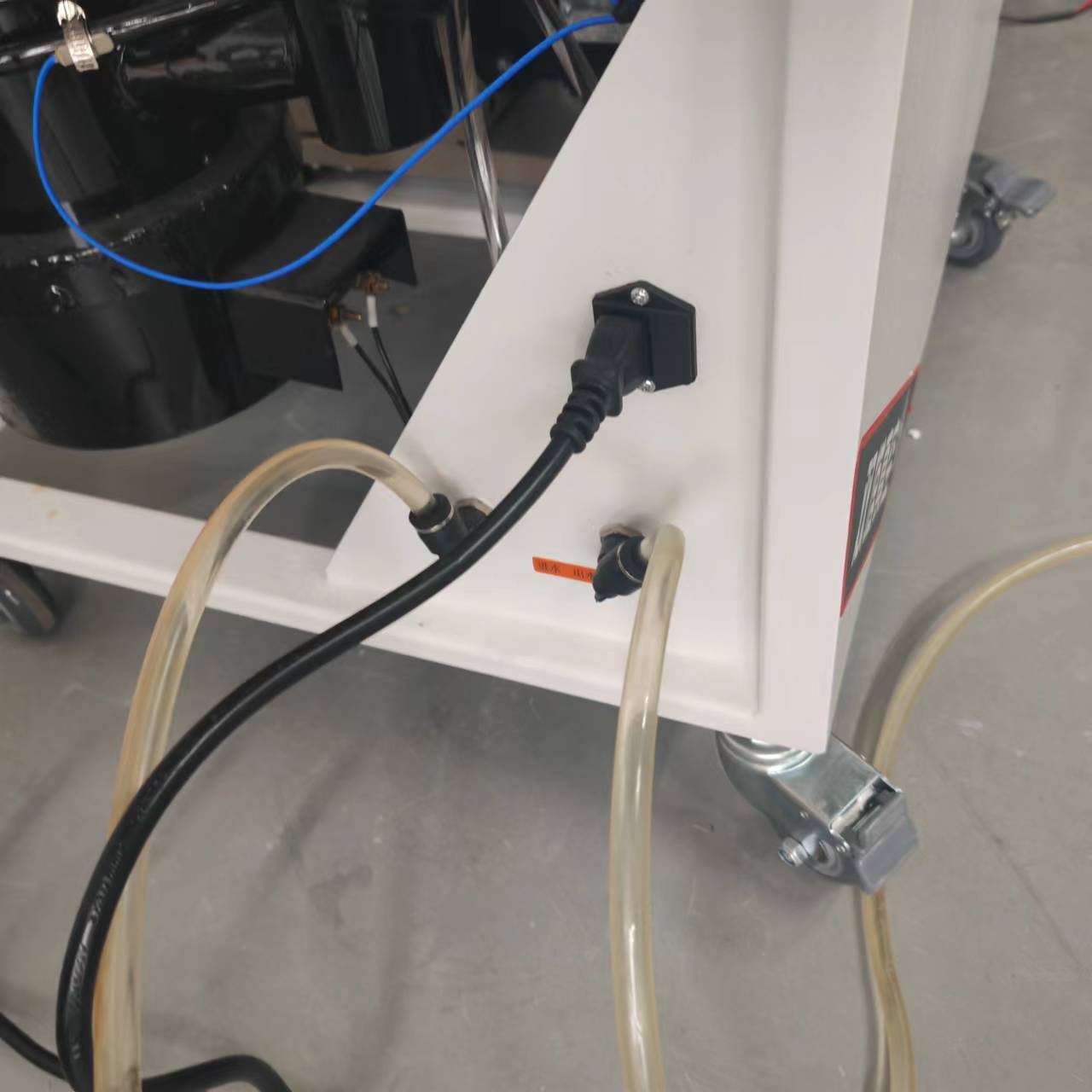

Vacuum system |

High vacuum molecular pump set: Diffusion pump unit Vacuum degree: 0.001Mbar KF25 quick connect, stainless steel bellows, manual flapper valve and flange, vacuum pump. Water Chiller connect vacuum pump |

|

Warranty |

One year limited warranty with lifetime support, excluding heating element,cooling fans,thermocouple and ceramic tube damaged by user. Attention: Any damages caused by the use of corrosive and acidic gases, and any damage from wrong operate and use are not under the coverage of One Year Limited Warranty. |

|

Standard package accessories: |

||

|

Electric Furnace |

1 set |

|

|

High temperature gloves |

1 pair |

|

|

Crucible hook |

1 pc |

|

|

Quartz tube |

1 pcs |

|

|

Stainless steel flange |

1 set |

|

|

Spare heating element |

2pcs |

|

|

Tube stopper |

2pcs |

|

|

10mm Air pipe |

|

|

|

User manual |

1 book |

|

|

Vacuum unit |

1 set |

|

|

Chiller |

1 set |

|

The parameter of vacuum system

|

No. |

Item |

Unit |

Specification |

|

1 |

MODEL NO. |

|

STKS-280 |

|

2 |

INLET PORT |

mm |

KF40+KF25 |

|

3 |

ULTIMATE PRESSURE |

Pa |

≤5× 10E-4 |

|

4 |

MAIN PUMPING SPEED |

L/S |

≥280 |

|

5 |

PUMP SPEED OF BACKING PUMP |

L/S |

3 |

|

6 |

DURATION OF GAS CONTAINER |

H |

1 |

|

7 |

TOTAL POWER |

KW |

1.8 |

|

8 |

POWER SUPPLY |

|

1-PH, 220V,50HZ |

|

9 |

POWER OF DIFFUSION PUMP HEAT |

KW |

1 |

|

10 |

DIFFUSION PUMP OIL |

|

#275 |

|

11 |

DIFFUSION PUMP OIL CONSUMPTION |

L |

0.5 |

|

12 |

COOLING WARTER INLET&OUTLET PORT |

MM |

10 |

|

13 |

COOLING WATER VOLUME |

L/H |

200 |

|

14 |

DIMENSION(W*D*H) |

MM |

550×560× 1010 |

|

15 |

WEIGHT |

KG |

110 |

The parameter of water Chiller

|

Model |

CW-5300 |

|

Compressor power |

0.94k 1.26HP |

|

Nominal cooling capacity |

8188Btu/h2.4kW 2063Kcal/h |

|

Max. pump flow |

15L/min |

|

Temperature control accuracy |

±0.5℃ |

|

Water tank volume |

10L |

|

Inlet and outlet size |

Rp1/2" |

|

Refrigerant |

R-410a |

|

Power supply |

220V 50Hz |

|

Total power |

1. 12kW |

|

Overall dimensions |

59 X 38 X 74cm (LX W X H) |

Product details:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

High Temperature 1400C Multi Zone Tube Furnace with Three Heating SectionNext :

Lab High Temperature 1500-1500C Dual Zone Rotary Tube FurnaceCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported