Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-PC-600C/CGPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

15 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

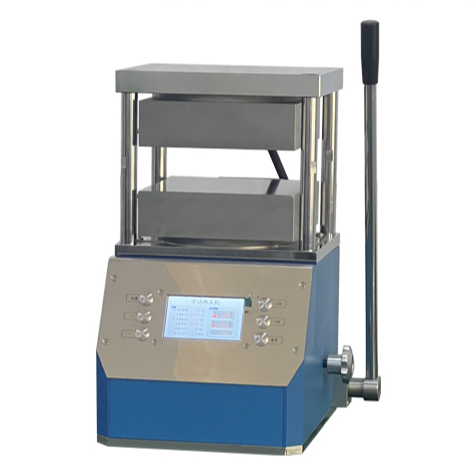

One year limited warranty with lifetime technical support300C 500C Lab Integrated Laminating Manual Heat Press Machine with Imported Heat Insulation Board

Application field

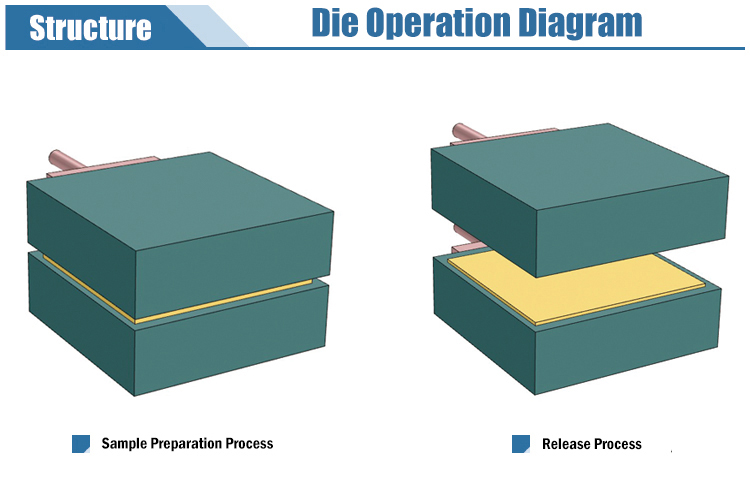

We are a professional manufacturer of hydraulic powder presses and dies. Our hydraulic presses feature small size , high pressure and high pressure control accuracy , and have been widely applied in scientific research , teaching, testing and chemical engineering. In addition, the products can be used together with Fourier infrared spectrometer, fluorescence spectrophotometer and other testing instruments to substitute for imported products.

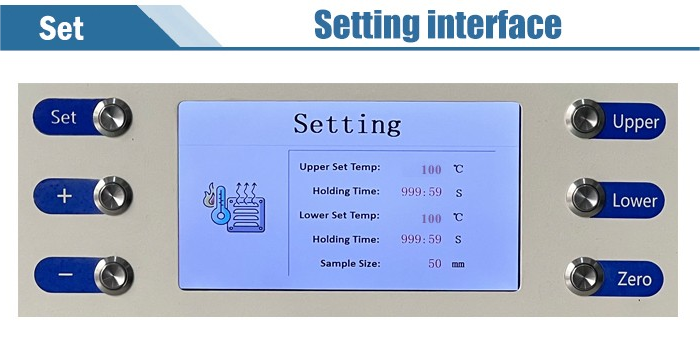

Set

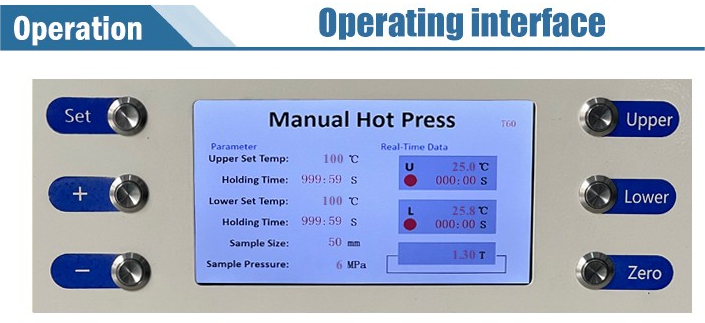

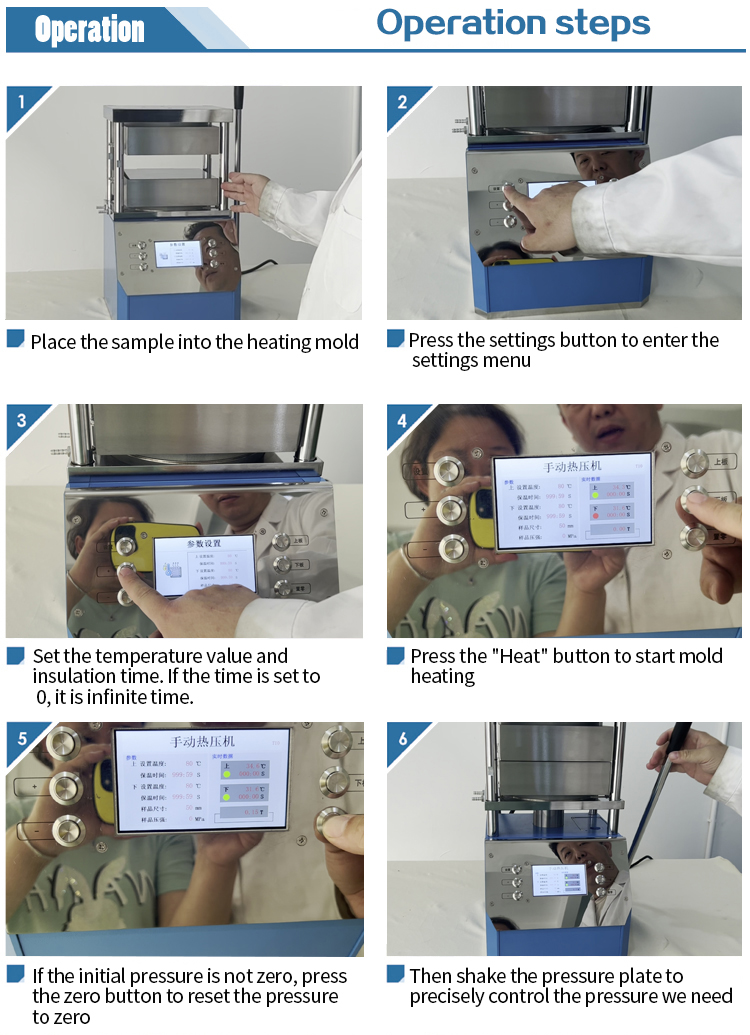

Set: In the operation interface, press the settings button to enter the settings interface, then press the settings button to move the settings content. After moving to the mold diameter, press the settings button again to return to the operation interface. Note: When the time is set to "0", it means that the time is set to infinity.

+: In the operation interface, press the "+" key to increase the setting number.

-: In the operation interface, press the "-" key to reduce the setting number.

Upper: Press the "Upper Plate" button on the operation interface, and the upper plate will start heating to the set temperature. After the automatic timing and constant temperature timer are completed,the heating will stop.Or press the "Upper Plate" button again to stop heating the upper plate. During the heating process, all setting buttons are invalid.

Lower: Press the "Lower Plate button on the operation interface, and the lower plate will start heating to the set temperature. After the automatic timing and constant temperature timer are completed,heating will stop.

Zero: If the sample is not in contact, but the device has already displayed pressure, it may be due to the weight of the heating plate. We can press the "reset" button to reset the pressure to zero.

Technical parameters

|

Instrument model |

PC-600C/CG(500℃) |

|

Pressure range |

0-5.0 tons |

|

Piston diameter |

Chrome plated cylinder φ50mm (d) |

|

Overall structure of main body |

Equipment without sealing connection to reduce oil leakage point |

|

Mold heating temperature |

Room temperature -300.0℃/500.0℃ |

|

Constant temperature time |

1sec~∞sec |

|

Temperature control precision |

0.1℃ |

|

Insulation method |

Imported heat insulation board |

|

Cooling method |

Water-cooled rapid cooling [water cooler optional] |

|

Mould size |

Double plate heating 120*120mm(M*N) |

|

Working space |

140*140*60mm |

|

Size of the whole machine |

250*230*390mm (L*W*H) |

|

Power supply |

700W(220V/110V can be customized) |

|

Main machine weight |

55Kg |

|

Dimensions of hot press |

|

|

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

300℃ 24T Lab Hot Manual Hydraulic Press with Φ110mm Chrome-plated Cylinder and Double Heating PlateNext :

Small Oil Press Automatic Powder Tablet Hydraulic Press MachineCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported