Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Item No.:

TMAX-RLG700LPayment:

L/C, T/T, Western Union, Credit Cards, PaypalProduct origin:

ChinaShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

Ⅰ、Measuring principle and application characteristics of laser thickness gauge:

Measuring sensor: high-precision laser displacement sensor.

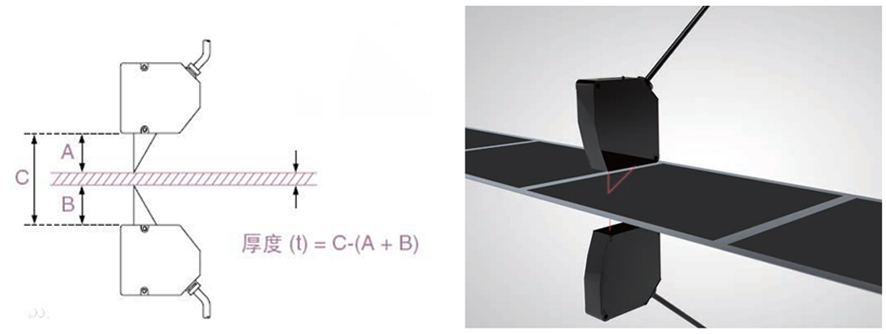

Measurement method: reflective optical geometric thickness measurement.

The two probes are installed on the same axis, and the triangular geometry method is used to measure the geometric thickness of the material by measuring the distance from the upper and lower surfaces of the material to the laser.

Ⅱ、Scanning frame:

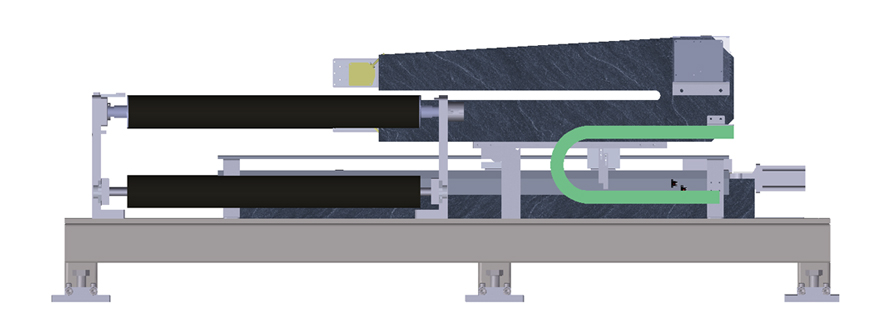

Due to the high requirements for the coaxial alignment accuracy of the upper and lower probes in laser measurement, only C-type scanning frame is suitable, and generally marble with small linear expansion coefficient is used

Or cast iron C-frame, as shown below:

The laser thickness gauge does not need to sample and calibrate the product, but only needs to calibrate the standard thickness sheet regularly.

Because the laser sensor has small measuring spot and high precision fine fringe resolution, it can be used to measure the size of the coating edge or the head and tail thinning of the lithium battery electrode.

Ⅲ、Application field:

It is mainly used for the thickness measurement of lithium battery pole after rolling, the outline and size measurement of lithium battery coating edge or head and tail thinning area, and the online measurement of other sheet, plate or coil thickness such as gypsum board, copper clad plate, metal calendering, rubber, etc.

Ⅳ、Performance index:

|

Model |

TMAX-RLG700L; TMAXRLG750L;TMAX-RLG850L |

|

Measurement method |

Scanning measurement, fixed-point measurement, cyclic fixed-point measurement |

|

Testing range |

0-1000um |

|

Spot size |

30*1200um |

|

Sampling distance |

1mm |

|

Repetition precision |

±0.4μm |

*The above data are based on the measurement of the lithium battery electrode sheet rolling press or coating thickness.

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

5V20A 64 Channel High Temperature and Negative Pressure Formation Machine for Lithium-ion Prismatic BatteryNext :

Automatic High Efficiency Roll To Roll Slitting Machine for Prismatic Battery ProductionCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported