Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-SPMPayment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

20 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

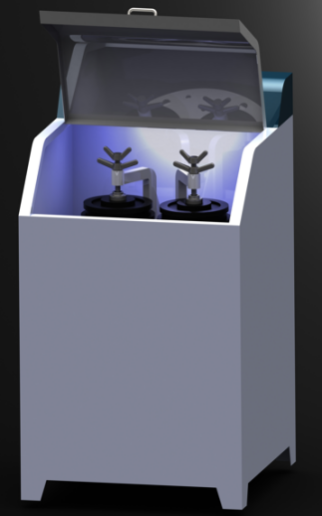

Sample making machine is mainly used for making powder of raw materials for laboratory use. Dedicated to crushing and grinding non-metallic minerals with a certain hardness, in the coal, coking, non-ferrous metal smelting, mining and other industries in the assay has been widely used. Such as: coal, coke, gangue, various ores, etc.. Crushing and grinding of the main components of the mantle has a common bonded steel type, high manganese steel type, wear-resistant alloy type, chrome steel type, tungsten carbide type and so on. According to the mantle of different steel materials, can crush the hardness of ore materials are different.

I. Working principle:

Sample making machine working mode is vibration grinding type. Material loaded in the mantle, the mantle has a crushing ring and crushing hammer, motor driven eccentric hammer rotating at high speed, in the high-speed rotation of the mantle to form a vibration and grinding function, the formation of vibration impact and friction will be made in 2-6 minutes the material in 2-200 minutes to make a 80-200 mesh (0.175-0.075mm) micro-powdered specimen, directly for the assay.

II. Technical parameters:

|

Model |

Spout size/number of bowls |

Feed size (mm) |

Discharge particle size (mesh) |

Production capacity (g) |

Power (KW) |

Reference external size (mm) |

Reference weight (KG) |

|

SPM-1 |

130*1 |

≤13 |

80-200 |

100 |

1.1 |

480X480X730 |

110 |

|

SPM-2 |

130*2 |

≤13 |

80-200 |

200 |

1.1 |

480X480X730 |

115 |

|

SPM-3 |

120*1 |

≤13 |

80-200 |

300 |

1.5 |

530X530X920 |

130 |

III. Product features:

1. The sample size is uniform, fast, reliable, high grinding efficiency.

2. The sample can be used directly without sieving, fewer procedures, high production efficiency.

3. Reasonable design: the whole machine sealed design, no dust pollution, in line with environmental requirements.

4. Smooth running, low noise, in line with the requirements of safe production.

5. Compact structure, easy maintenance, convenient operation.

6. At the same time can grind 1-3 samples.

7. Grinding bowl sealing without sample loss, and the use of special wear-resistant materials, long service life.

IV. Pictures

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Lab Low Temperature Frozen Tissue Grinder Mill Machine with Stainless Steel Inner CavityNext :

Agate Bowl Mill Grinding Machine for Electronic Resin Chemical Micro Powder GrindingCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported