Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-ZY-TB-A4Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

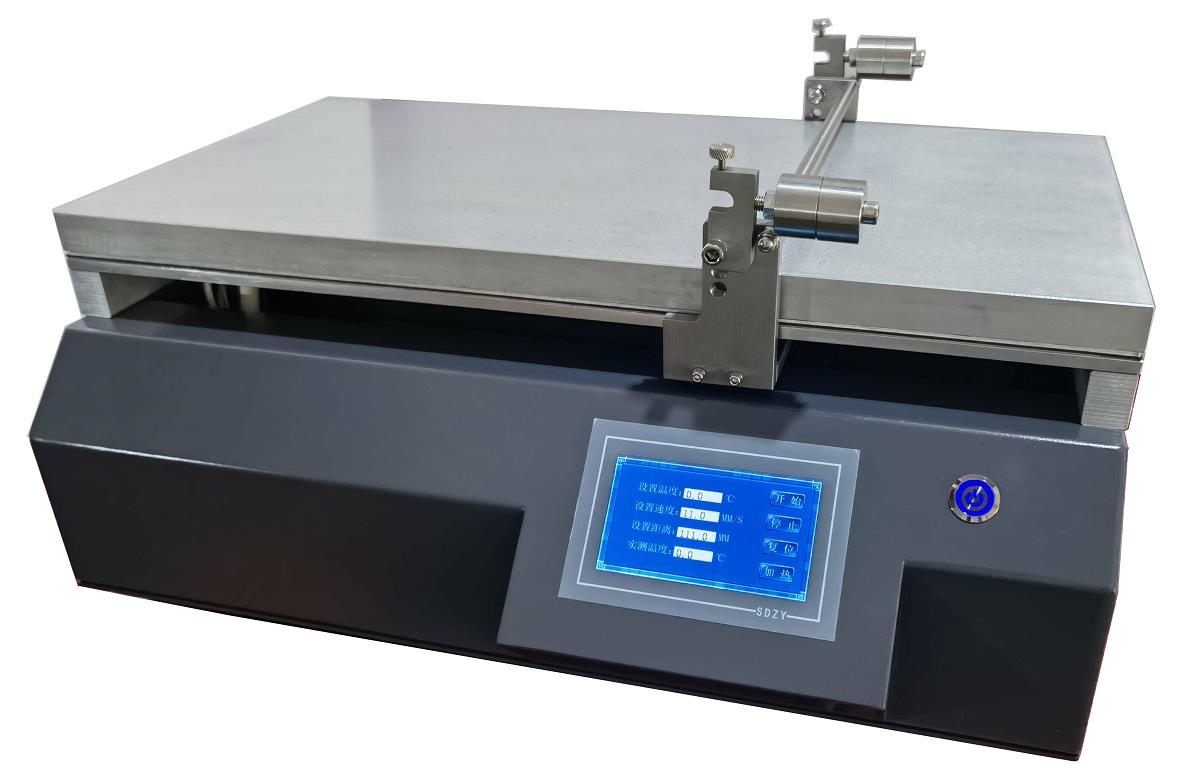

Two years limited warranty with lifetime technical supportHigh Temperature Touch Screen Type Vacuum Coater Equipped with Wire Bar Tool And Vacuum Pump

Touch Lab ZY-TB wire bar coating tester is the latest upgrade for coating precise wet film on different substrates and is carefully designed to repeatedly and continuously prepare smooth, flat and flawless test samples.

Newly upgraded, touch screen control, user-friendly human-machine interface;

Precise control of travel speed and running distance;

Newly upgraded hardware, more stable operation.

Uses:

As the main factors affecting the coating are the speed of the coating and the pressure applied to the applicator, the coating applied by hand is often inconsistent, especially when the difference is greater between different people, which makes it difficult to compare test results between samples. Our automatic film applicator allows the operator to easily apply precise wet films on different substrates, greatly improving the repbarucibility of the coated film.

Main parameters:

Machine dimensions (L*W*H): 622*440*450mm

Coating speed: 5-180mm/s

Coating area: 300*400mm

Wire bar specification: precision ±0.001mm, effective coating width 300mm (coating thickness to be determined according to wire bar model)

Vacuum hole: φ1mm

Hole spacing: 20*20mm

Heating temperature: room temperature-150°C

Temperature accuracy: ±3℃

Main machine using power supply: 220V/50Hz

Weight: 55KG

Vacuum pump external

Pbaruct features:

Precise control of test speed and distance, higher coating accuracy

Touch control operation, humanized human-machine interaction interface

New hardware upgrade, more stable operation.

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Newly Upgraded Wire Bar Type Coating Machine with Touch Screen Control FunctionNext :

Lab 200C High Temperature Wire Bar Doctor Blade Integrated Coater Device with Heating FunctionCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported