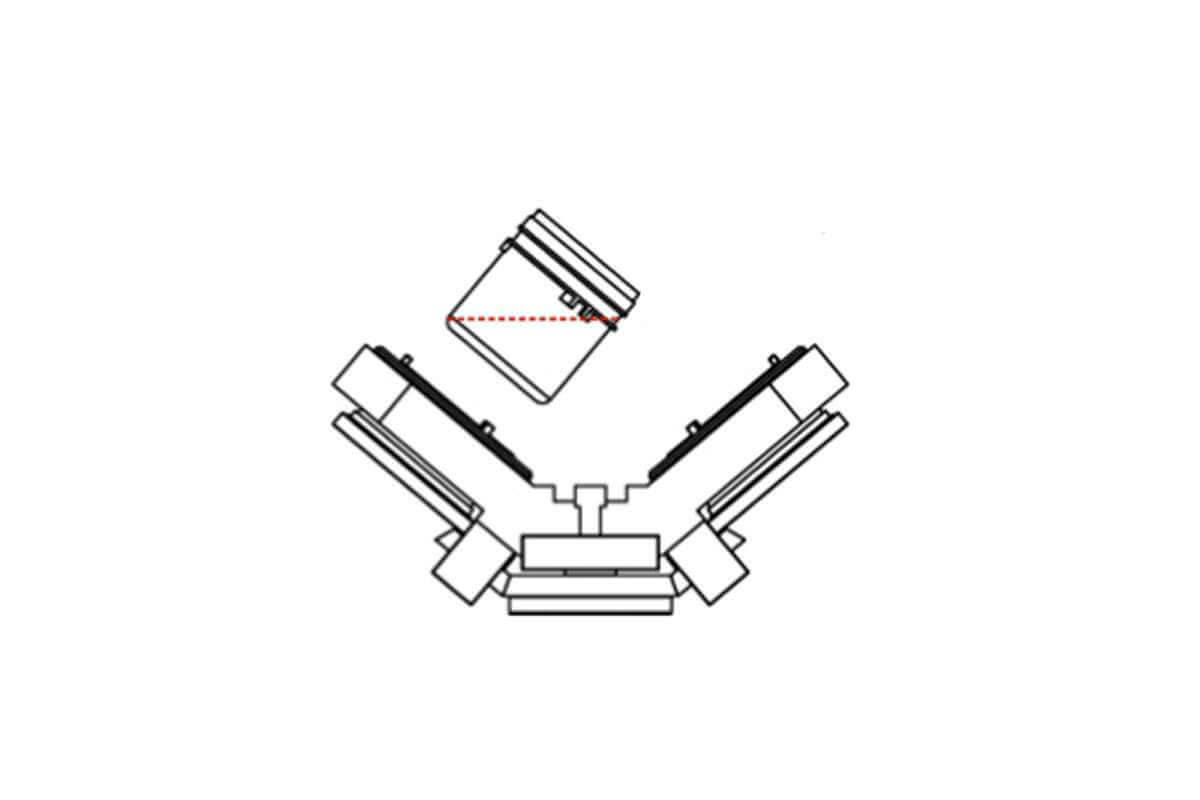

Vacuum Planetary Centrifugal Mixer Machine With Two 300 ML Cups & Optional Independent Speed Control

The planetary centrifugal vacuum mixer MSK-PCV-300-LD is designed for mixing and deaerating various kinds of liquid, slurry, paste, and powder materials. It could be used for mixing and homogenizing nanopowders, nanotubes, ceramics powders, battery powder/slurry, metal powders, and especially high viscosity slurry/paste. The vacuum mixing capability is integrated for best mixing results. The standard package includes two 300 mL containers and counter-weights. High-throughput adapters are also available for 6 samples (7 ml per sample) mixing per batch.

SPECIFICATIONS

Features

|

-

Compared with other brands of the planetary centrifugal mixer, MSK-PCV-300 has the following unique features:

-

Mixing under vacuum for deaeration

-

Dual containers for larger quantity

-

Minimized contamination (no metal mixing blade)

-

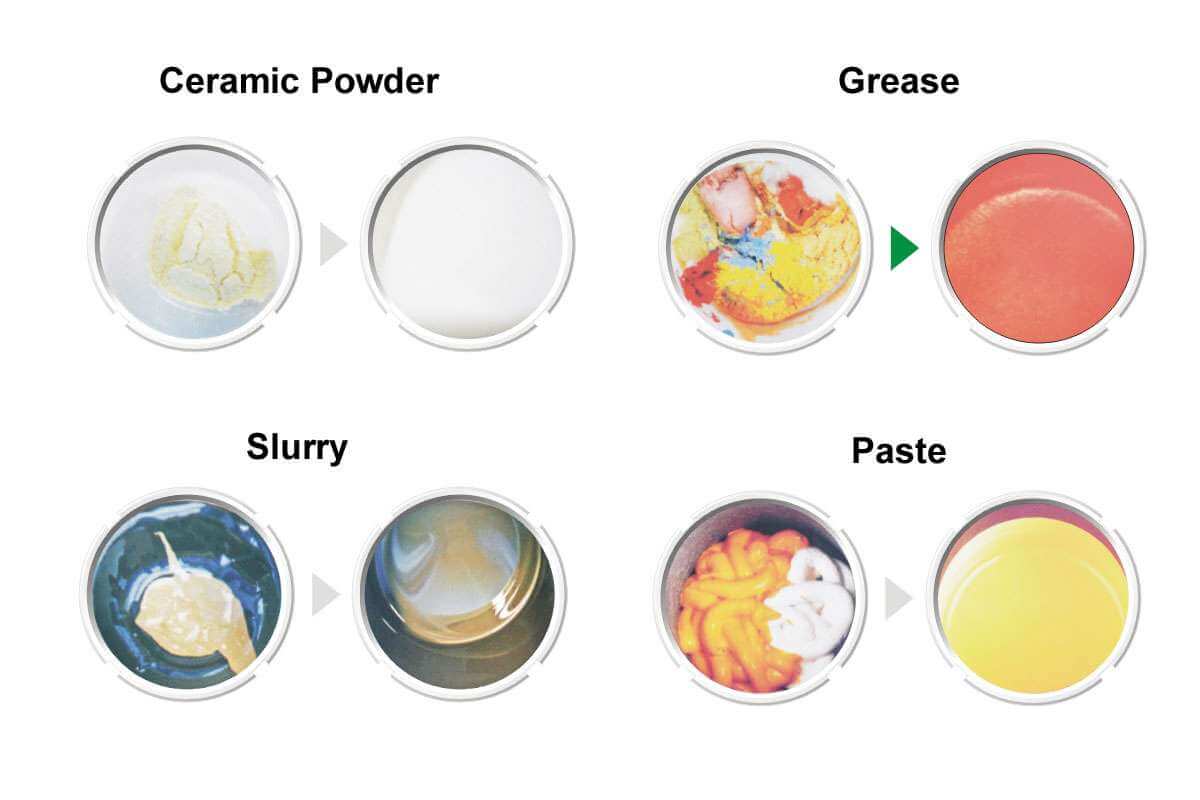

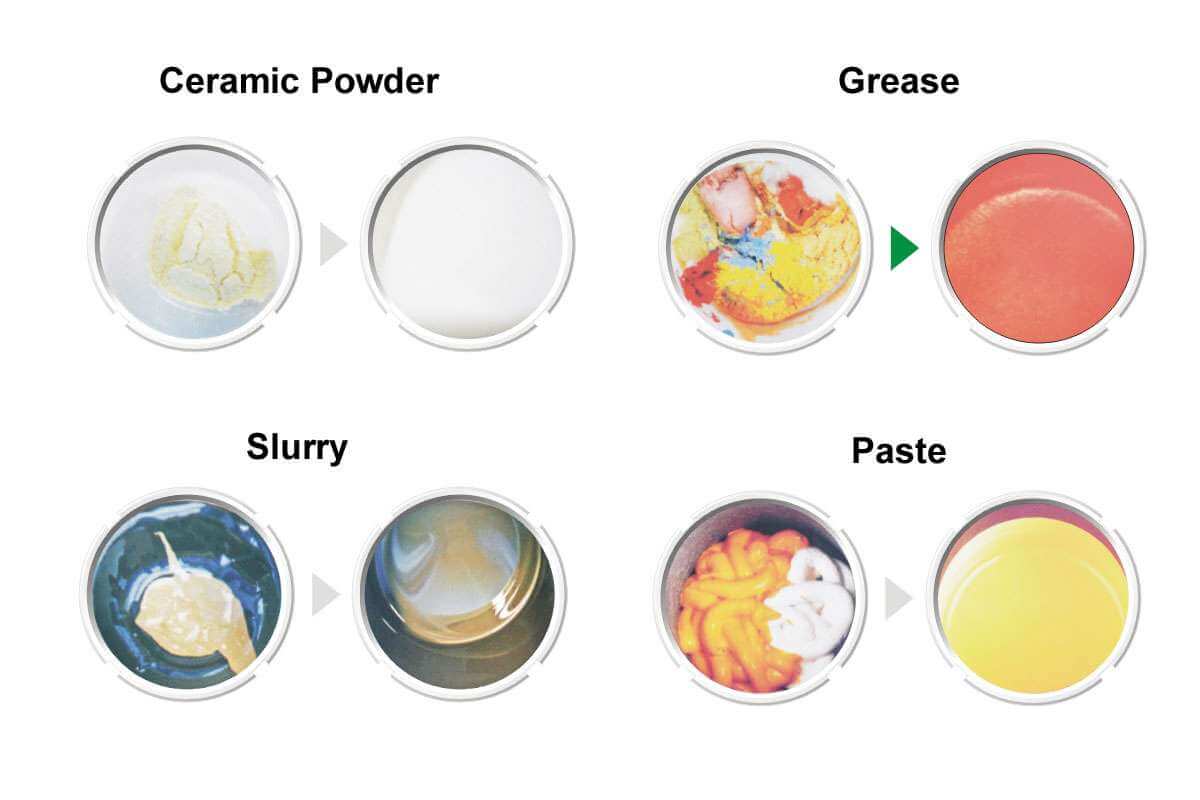

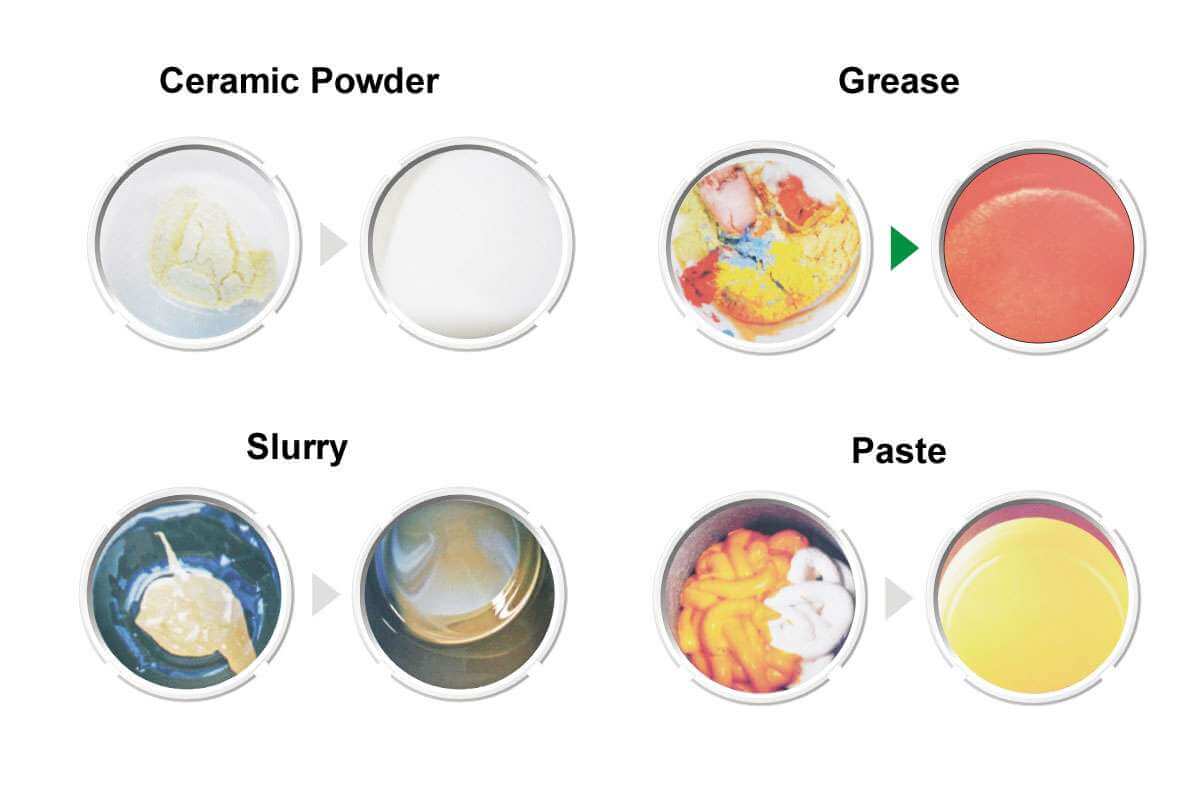

Sample Materials

-

Nanopowders, ceramic powders

-

Grease

-

Slurry

-

Paste

|

|

Voltage Input

|

-

Single Phase AC 208 - 240V, 50/60 Hz

|

|

Power

|

-

Maximum: 2000 W

-

Motor Power: 750 W

|

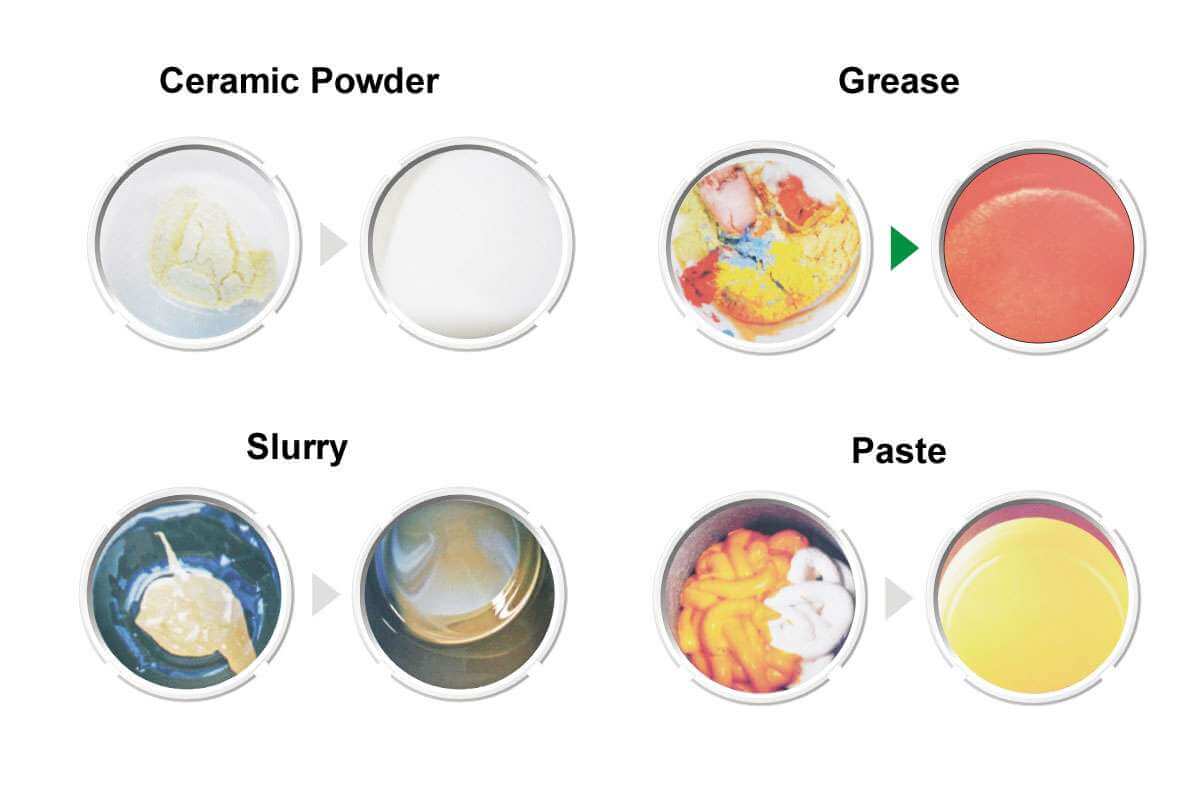

Mixing

|

-

Planetary Centrifugal Vacuum Mixing

-

The centrifugal force of rotation and revolution induces convection, homogenizing the materials

-

With the vacuum pressure, submicron air bubbles can be efficiently eliminated from the materials

|

|

Vacuum Capability

|

-

Pumping Rate: 165 L/min

-

Ultimate Vacuum: -95 kPa

-

Built-in vacuum pump with integrated control

|

|

Speed

|

-

Fixed speed ratio ( 0.6X between main plate revolution and container rotating )

-

Sample Platen Rotation (revolution motion):600 rpm - 2,000 rpm (adjustable)

-

Container Spin (rotation motion):360 rpm - 1,200 RPM (fixed at 0.6X of the revolution speed)

|

|

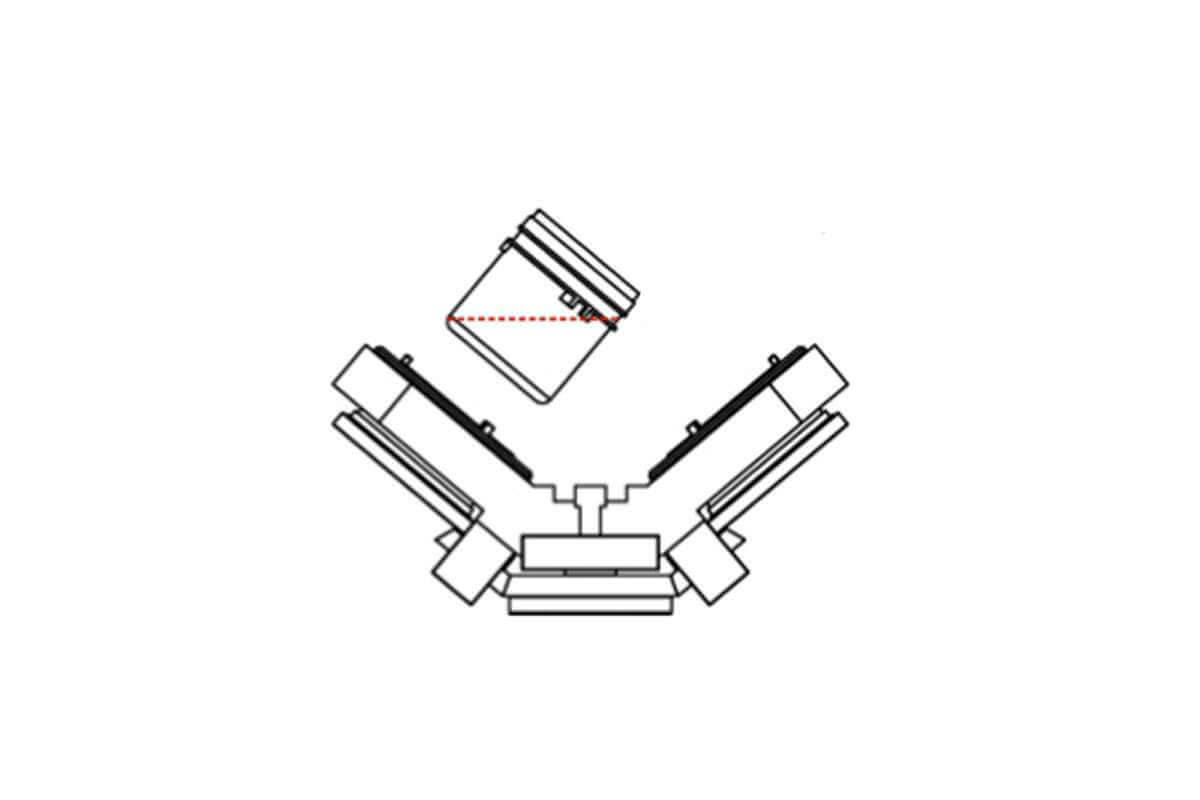

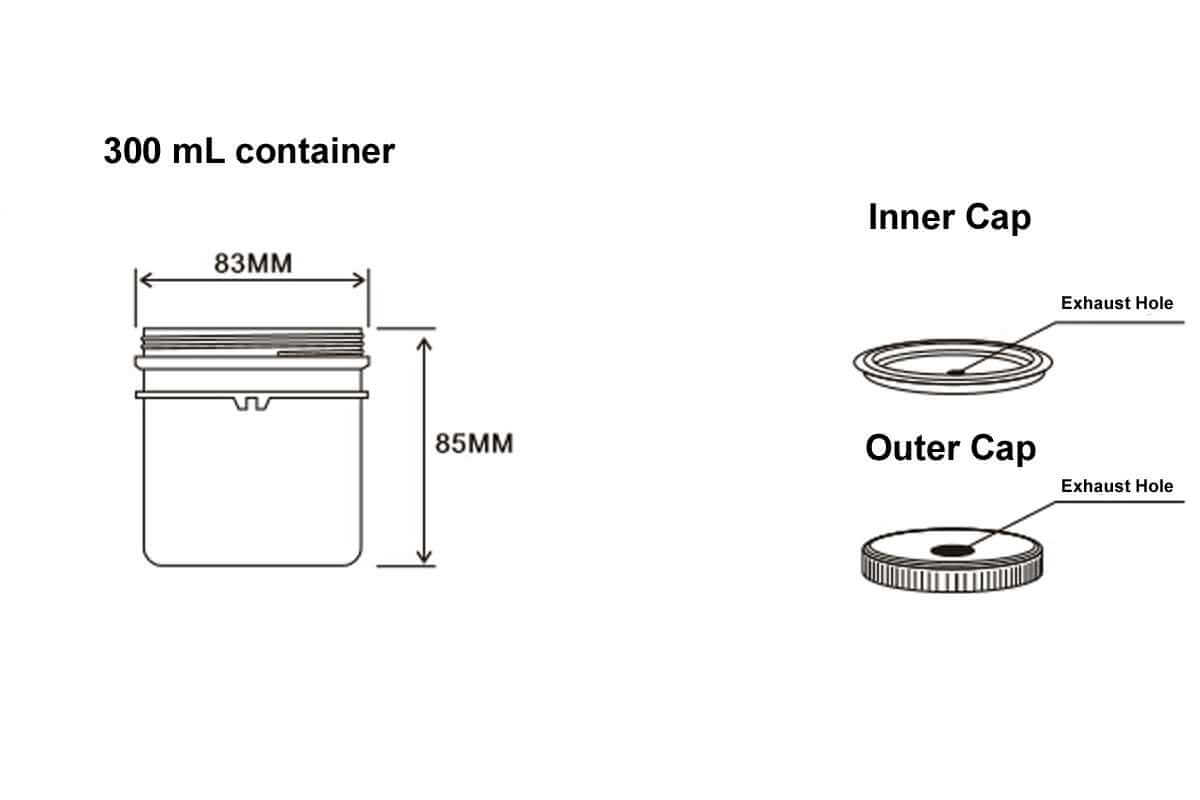

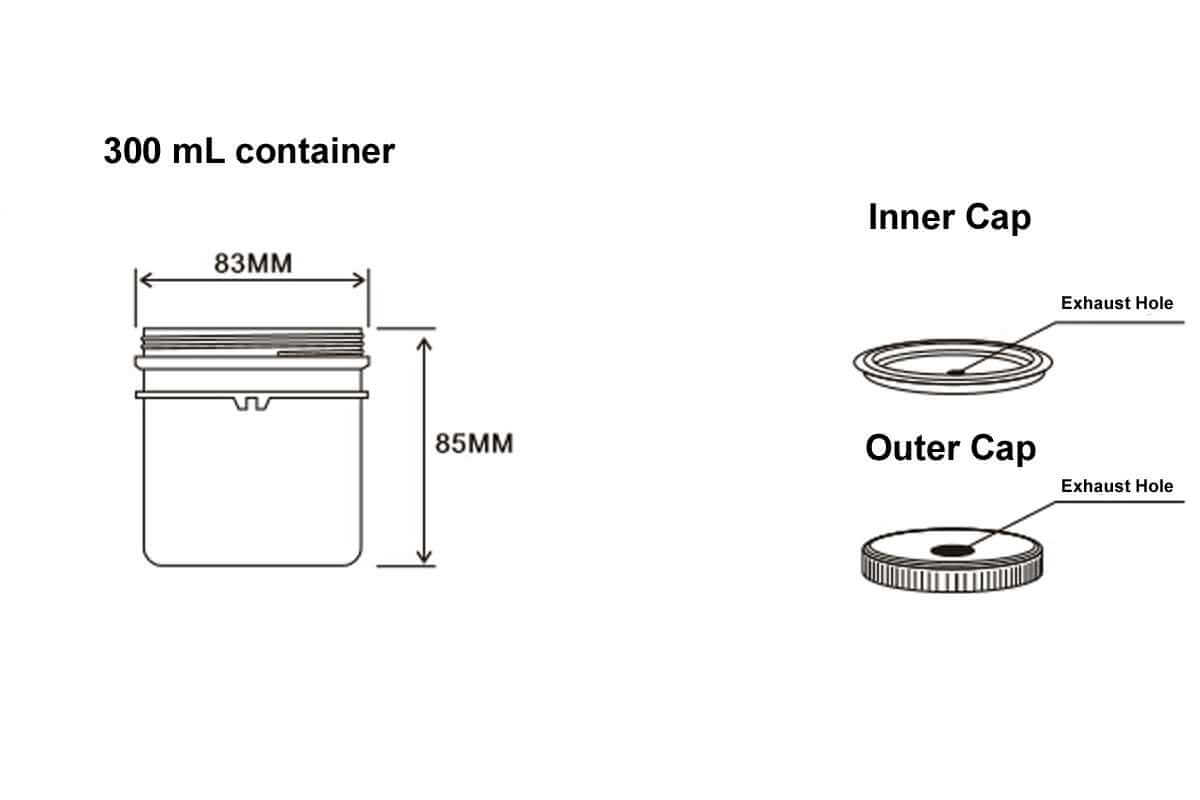

Containers and Counter-Weights

|

-

Two standard containers and counter-weights are included

-

Two 300 mL containers with gas vent, made of high-density Polyethylene ( Pic 1, 2 )

-

Counter-weights (10, 20, 50 g) with adapter, made of high-density Polyethylene (pic 3)

-

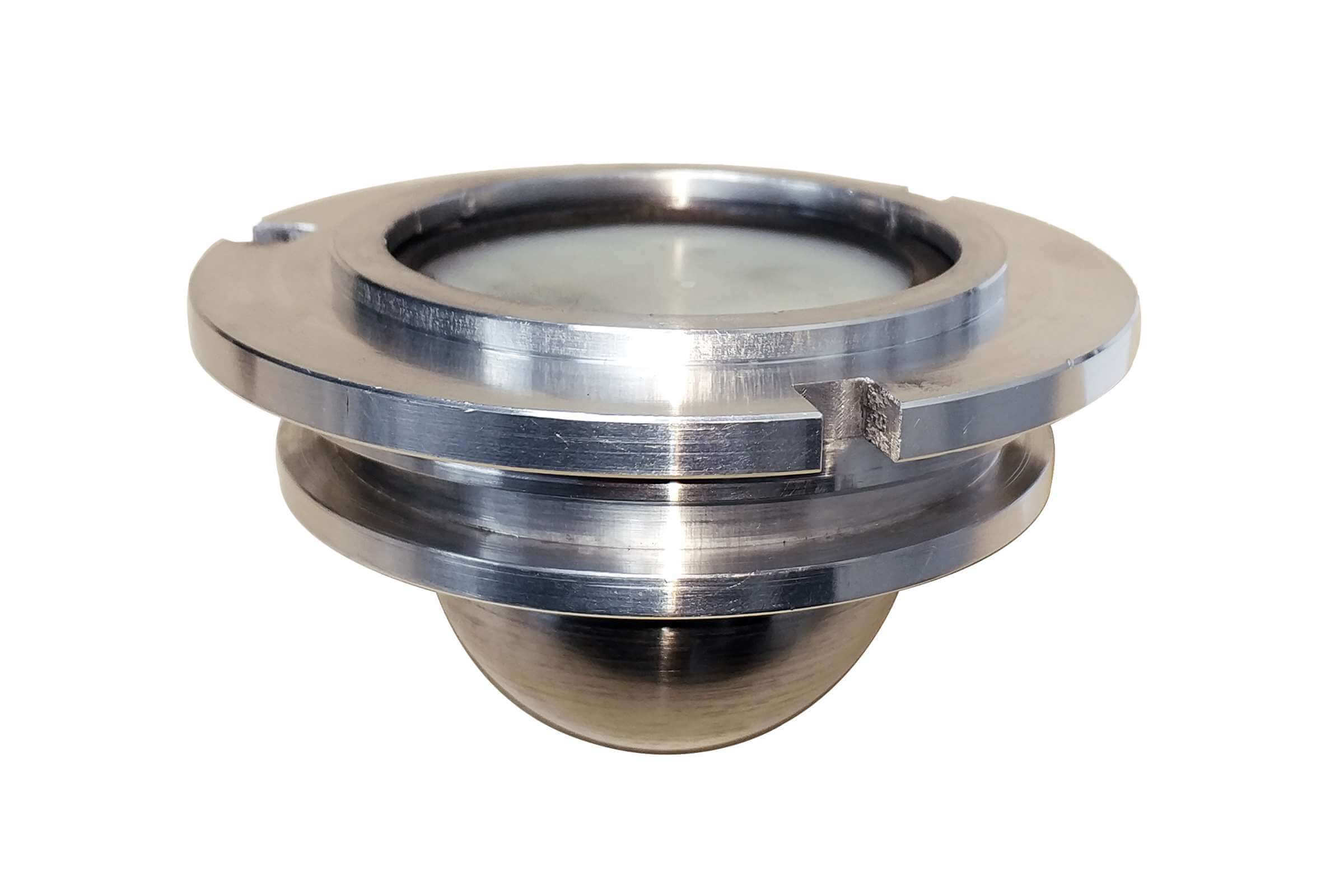

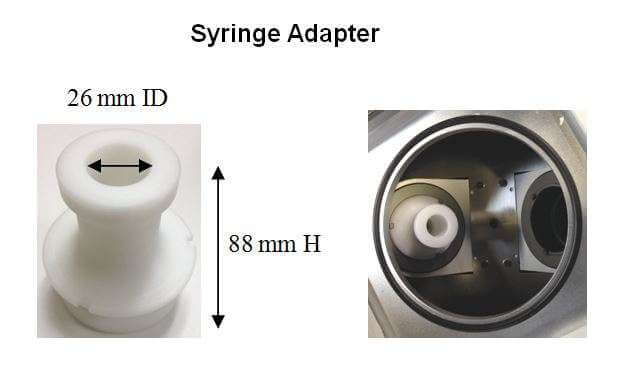

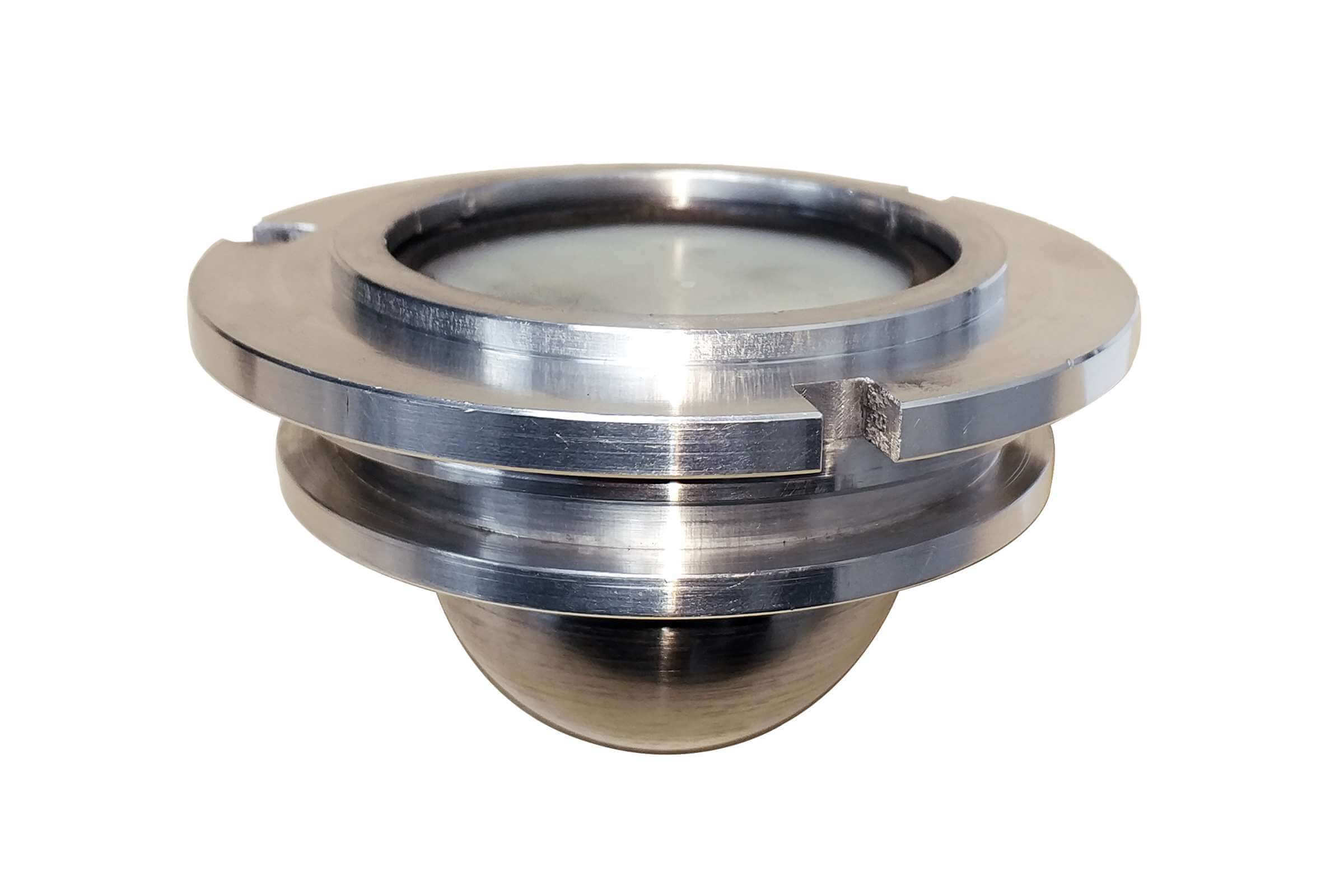

For ball milling application, please choose stainless steel liner, which will reduce jar compacity to 200 ml ( Pic 4)

Pic. 1 Pic. 1  Pic.2 Pic.2  Pic. 3 Pic. 3  Pic. 4 Pic. 4

|

|

Optional

|

-

Optional containers, which can be ordered at MTI at extra cost:

-

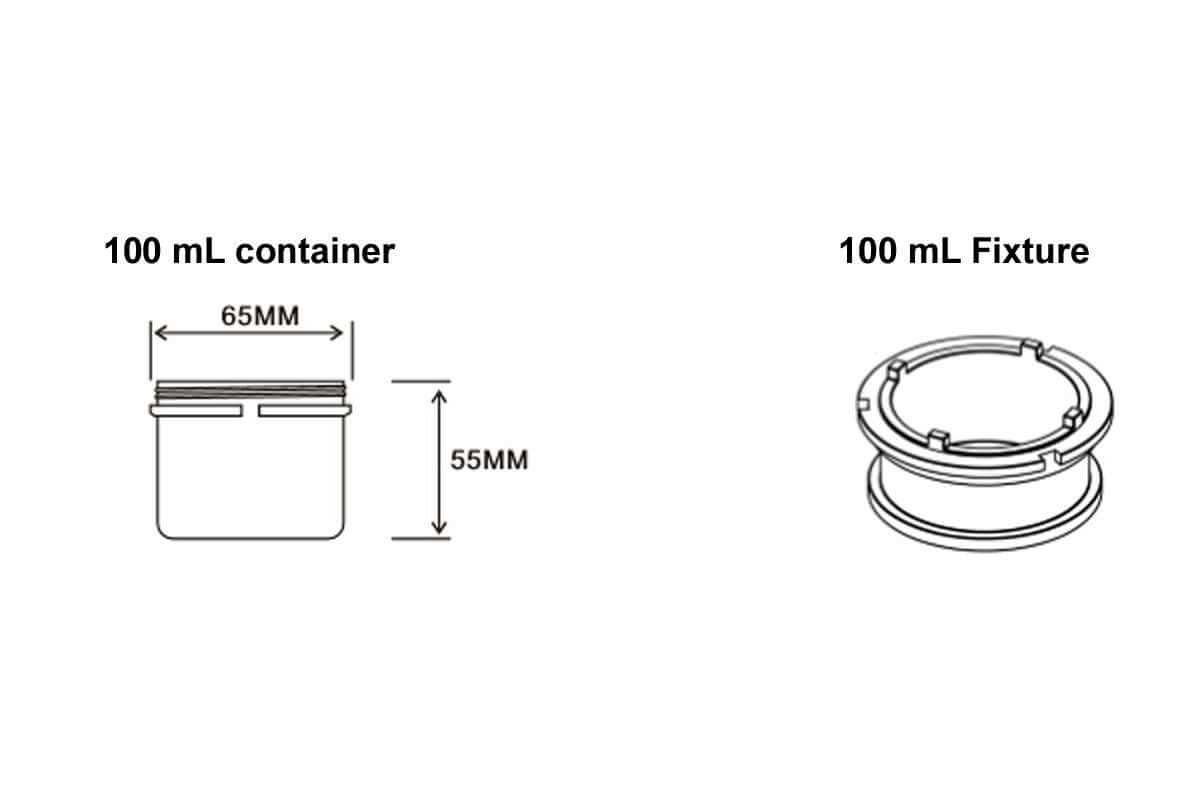

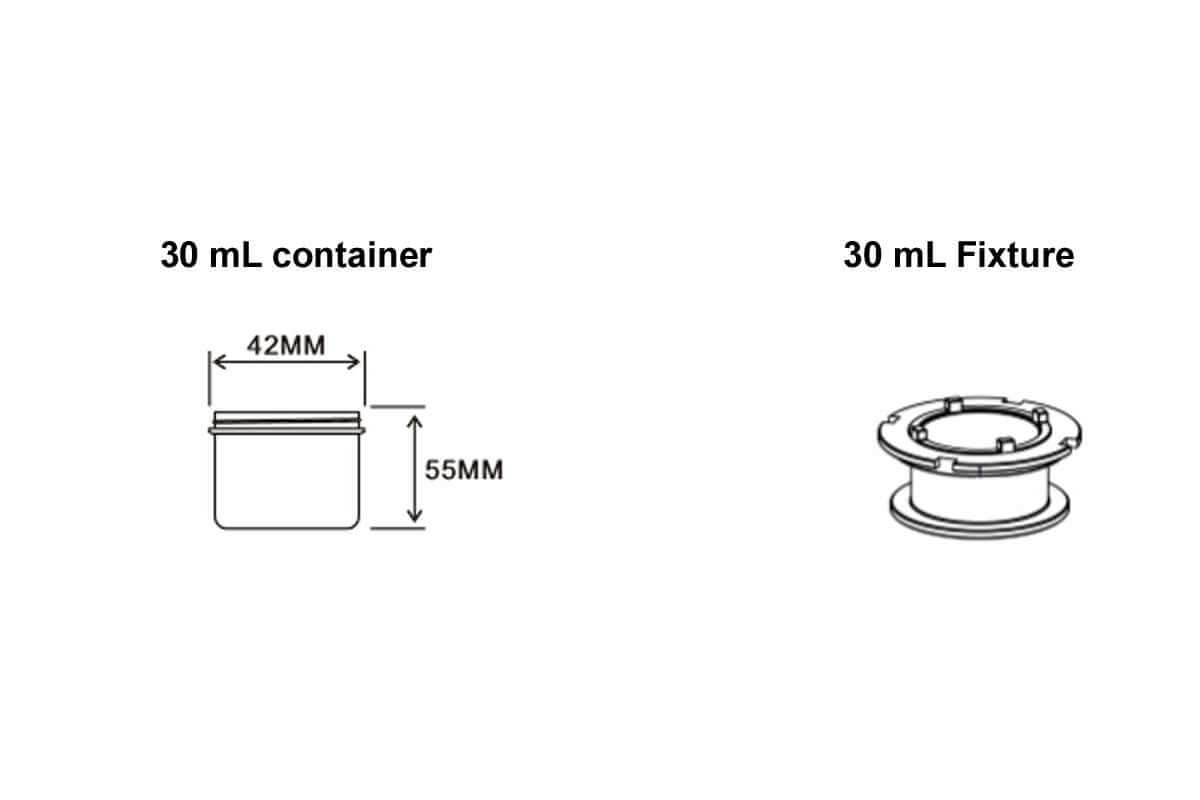

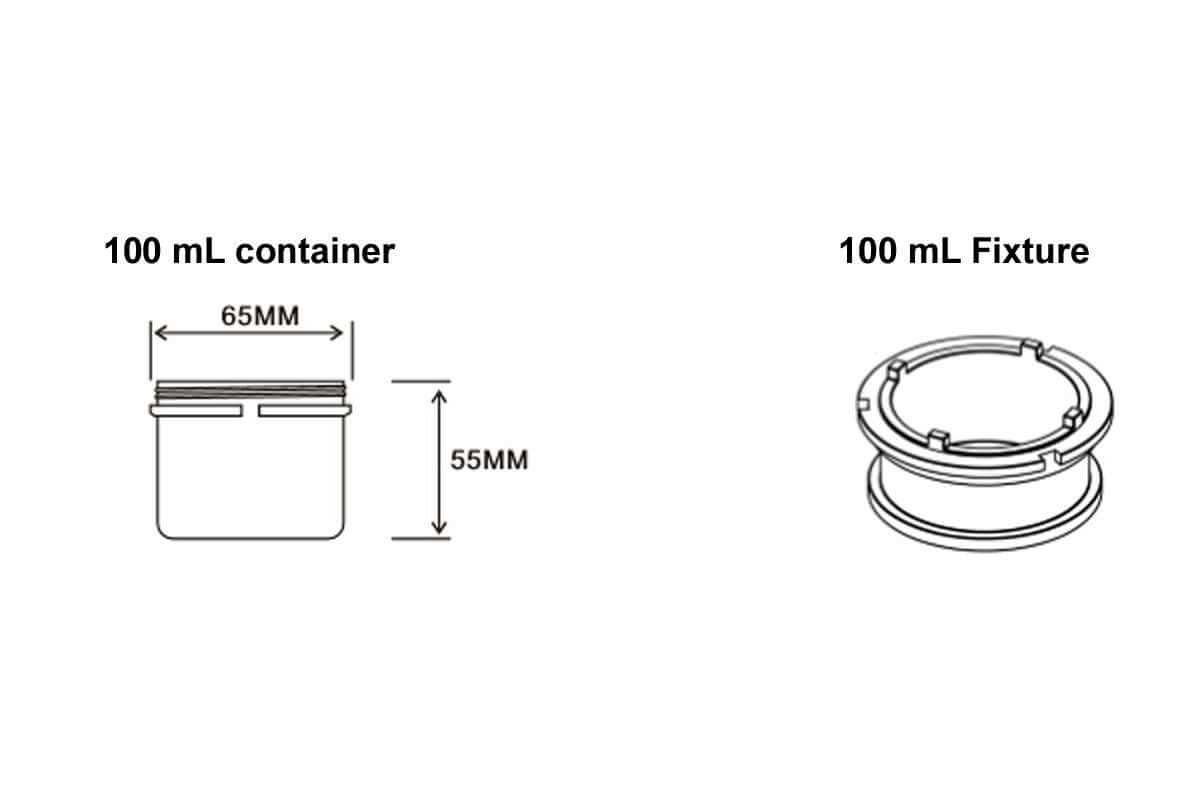

Two 100 mL containers (not included) with adapter and gas vent, made of high-density Polyethylene

-

Two 30 mL containers (not included) with adapter and gas vent, made of high-density Polyethylene

-

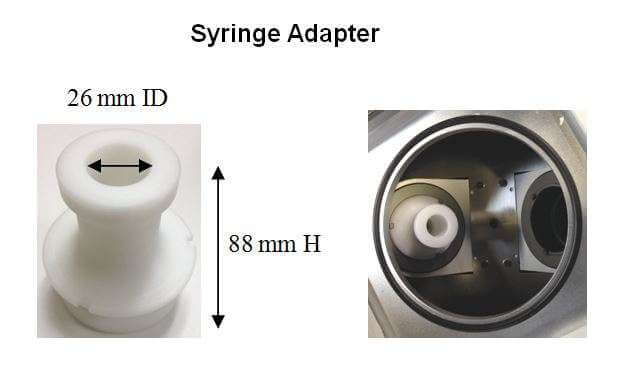

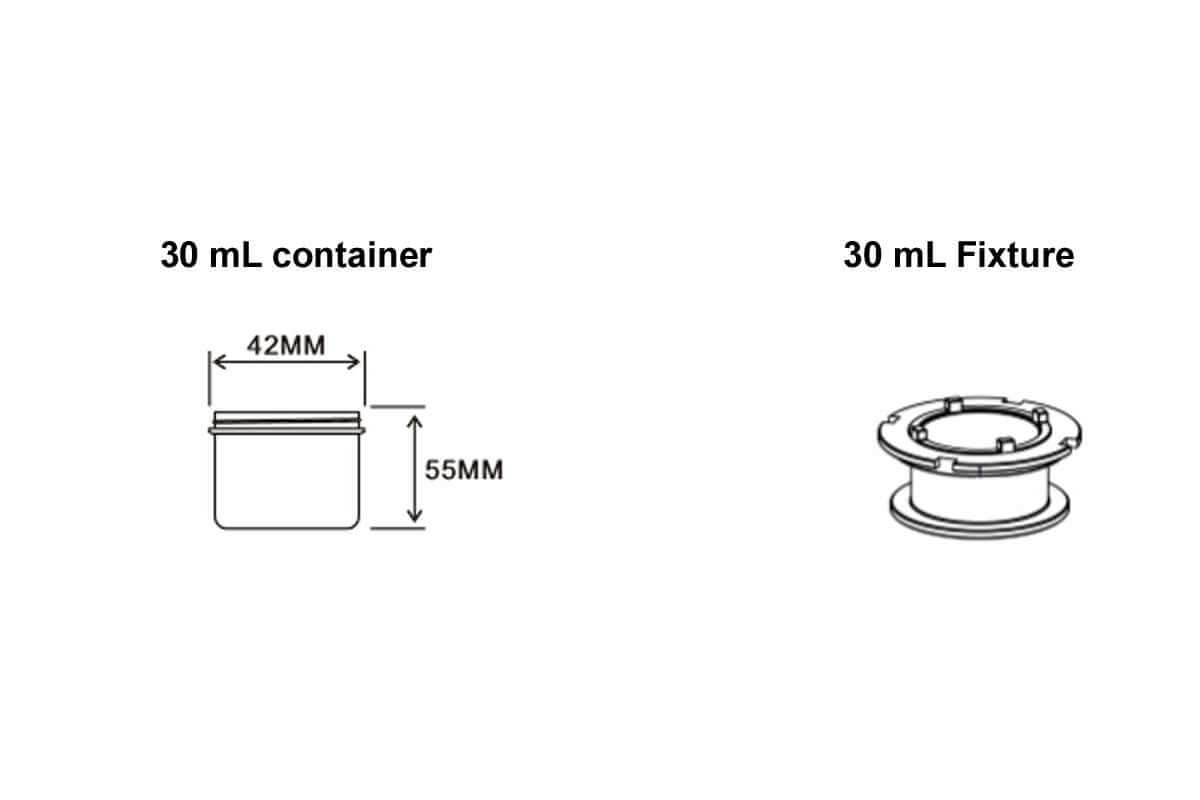

26 mm Dia. adapter for 30 mL syringe (not included), made of high-density Polyethylene

-

Two 3-container-sets (7 ml, 16 mm ID x 90 mm H) in one adapter are available for high throughput research (6 samples per batch)

-

You may order stainless steel container for ball milling application (Pic second to the right)

-

You may also order stainless steel container with a thicker wall for smaller sized ball milling application (the rightmost pic)

|

|

Max. Mixing Volume and Weight

|

|

Container

|

Max Sample Volume

|

Max Sample Weight

|

Max Gross Weight (Container Included)

|

|

300 mL

|

150 mL

|

140 g

|

300 g

|

|

100 mL

|

50 mL

|

45 g

|

80 g (adapter not included)

|

|

80 mL(SS)

|

60 mL

|

90 g

|

300 g (adapter included)

|

|

30 mL

|

15 mL

|

12 g

|

20 g (adapter not included)

|

-

Attention: Sample overload might damage the motor and/or cause spilling. Follow both the volume and weight limit when loading the

|

|

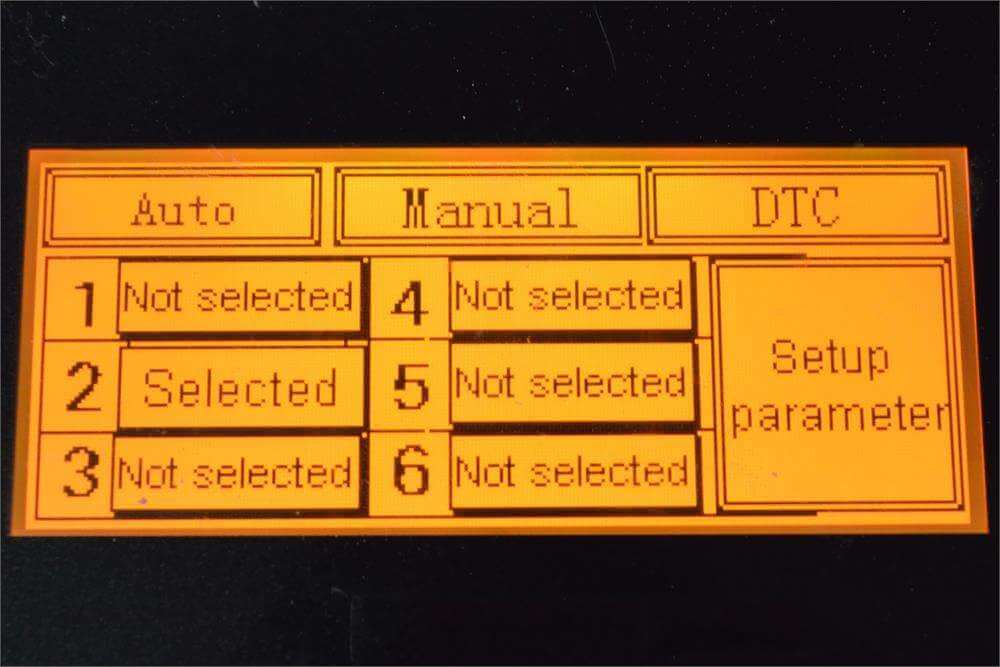

Program

|

-

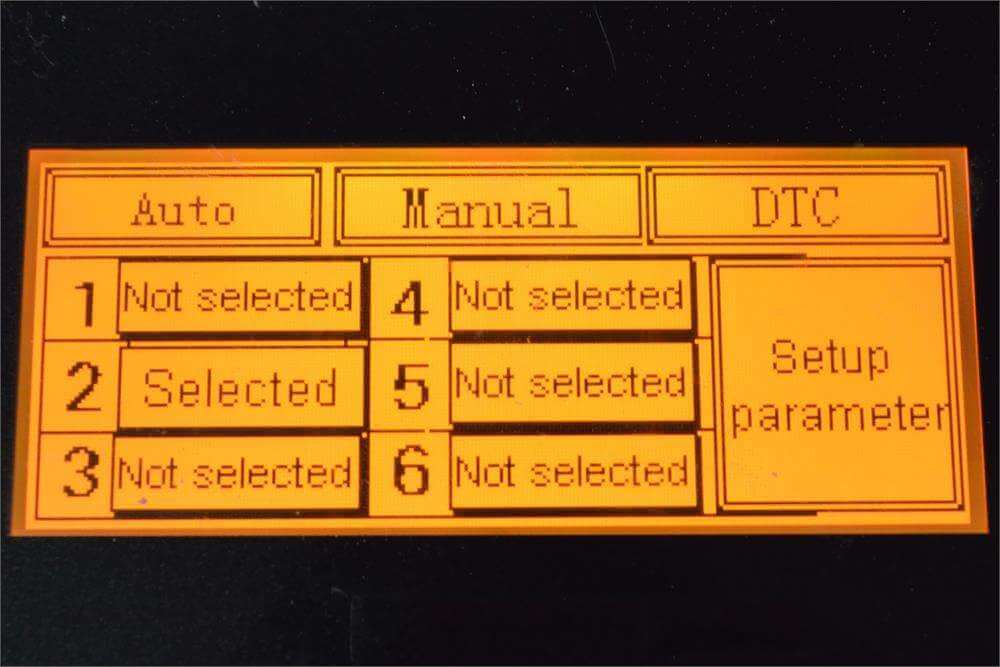

Store up to 6 programs in memory, as shown in Fig.1

-

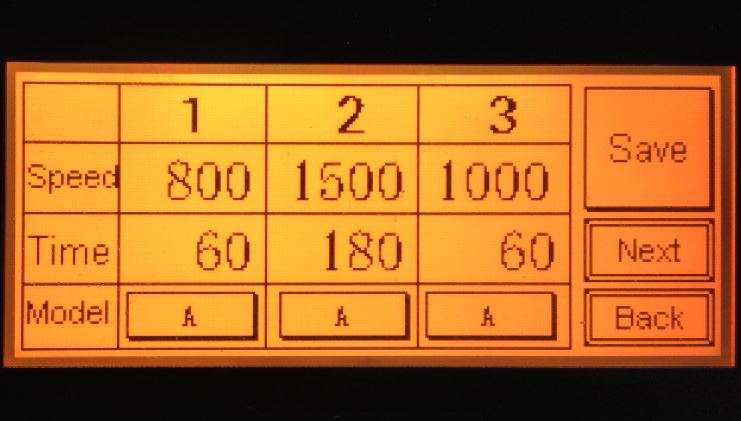

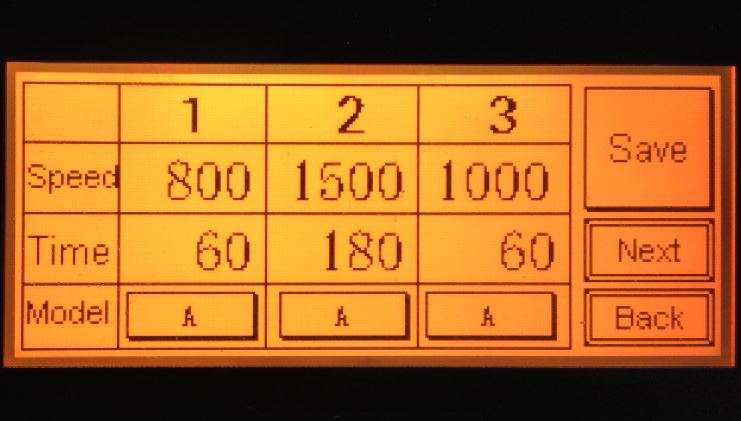

3 programmable segments, as shown in Fig.2. For example:

-

800 rpm revolution speed (480 rpm rotation speed) for 60 sec;

-

1500 rpm revolution speed (900 rpm rotation speed) for 180 sec;

-

1000 rpm revolution speed (600 rpm rotation speed) for 60 sec.

-

Maximum running time for each segment is 200 sec. Maximum total running time is 600 sec

-

The rotation direction could be either clockwise (mode A) or counter-clockwise (mode B)

Fig.1 Fig.2

|

|

Safety and Protection

|

-

Safety warning and interlocks are integrated. The unit automatically stops when

-

The unit is overloaded with the sample

-

The sample is loaded in an unbalanced way

-

The top cover is opened

|

|

Warranty

|

-

One year limited standard warranty with lifetime technical support

|

|

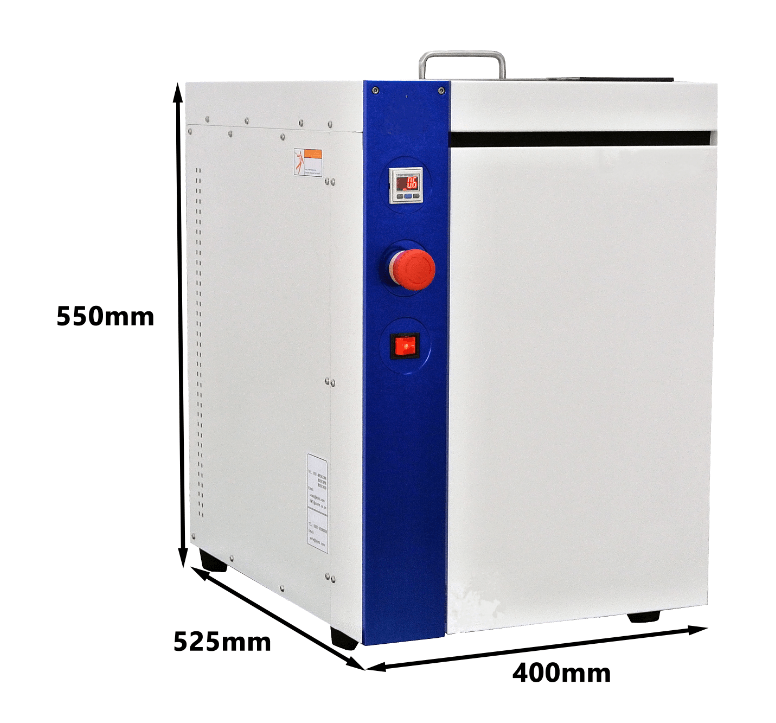

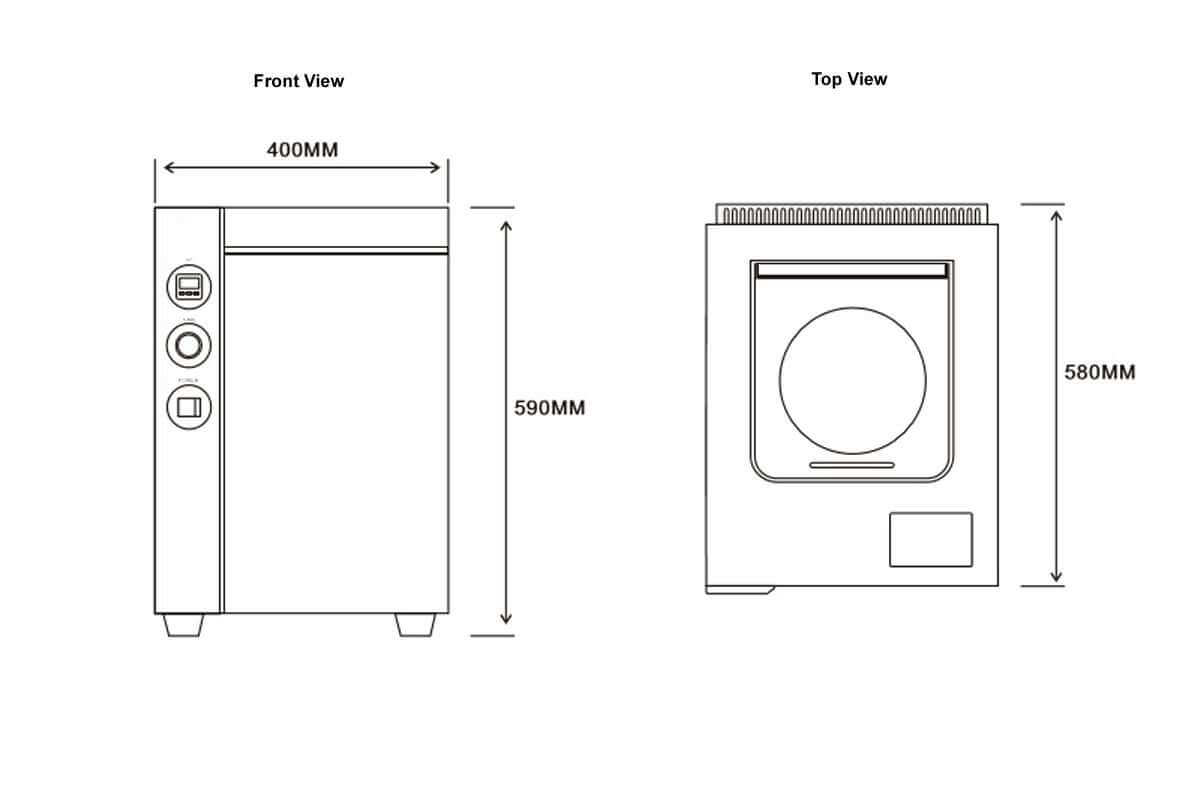

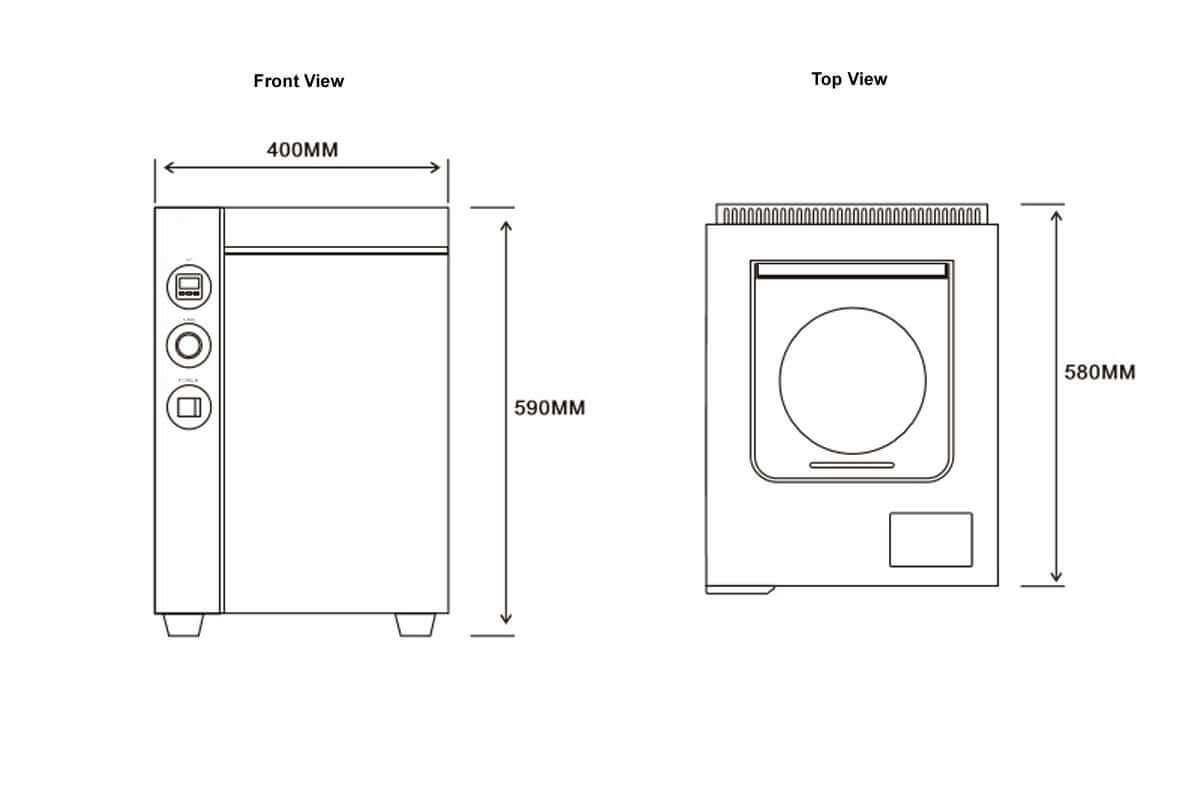

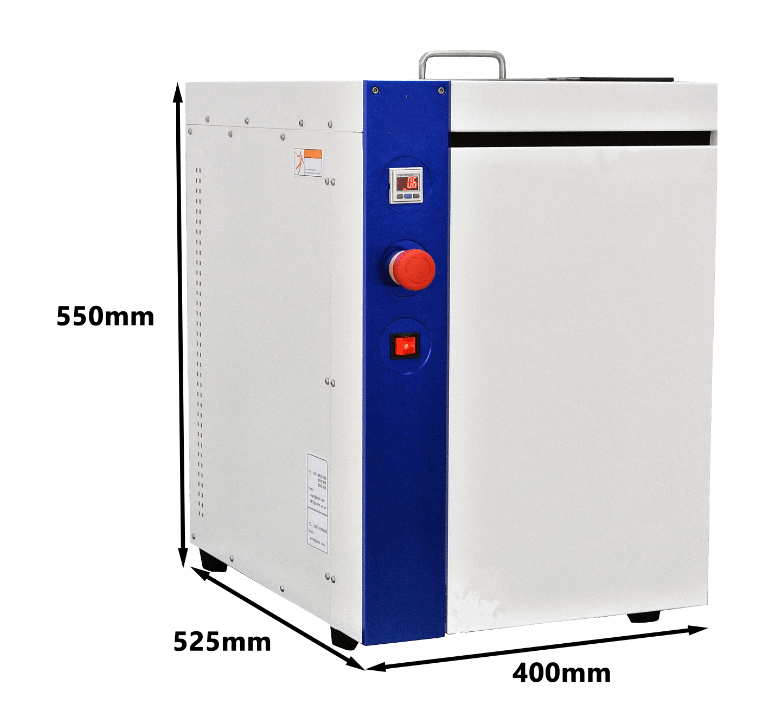

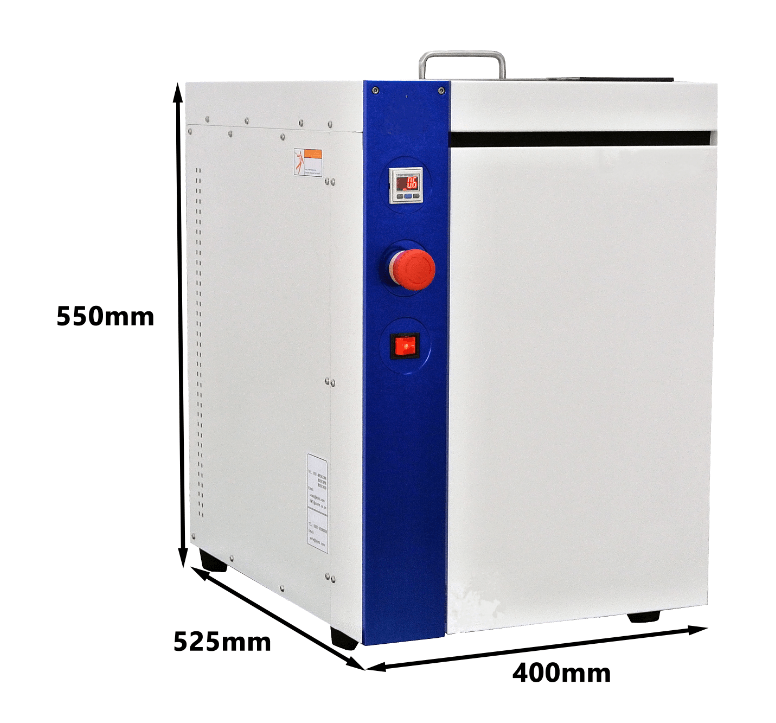

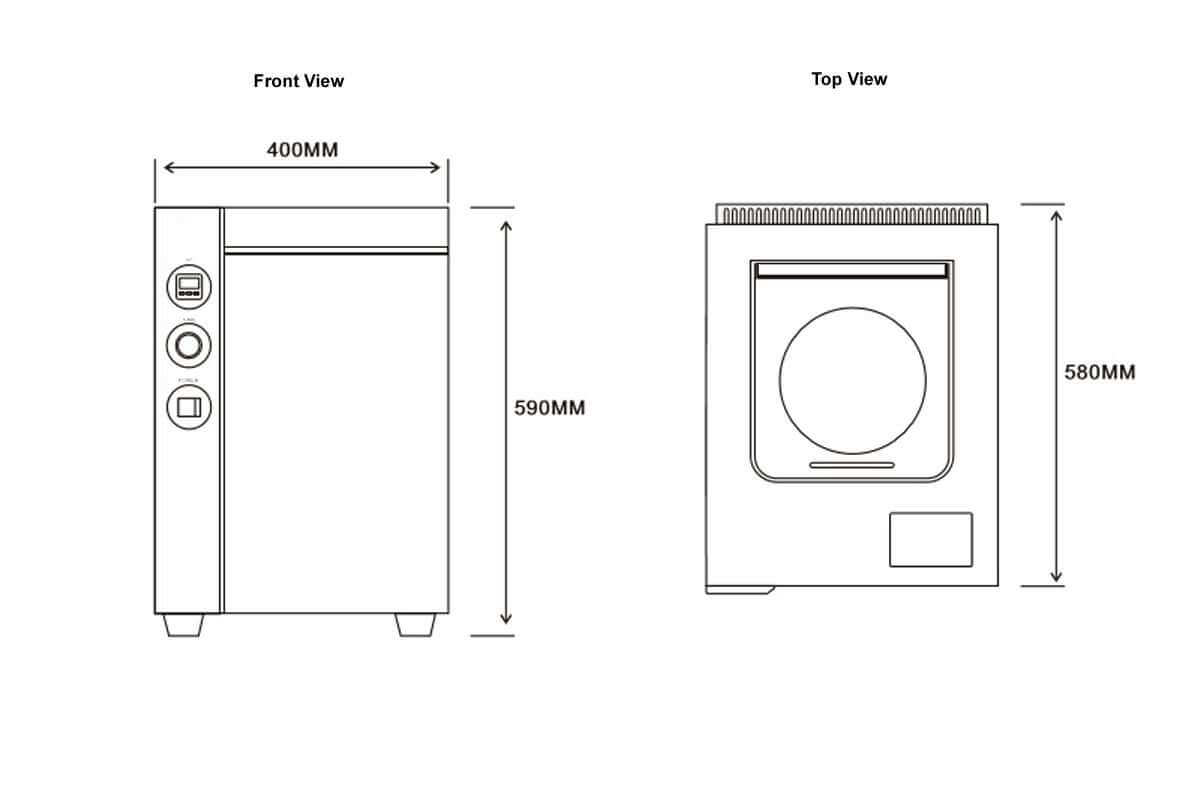

Dimension

|

-

400 mm (W) x 590 mm (H) x 580 mm (D)

-

|

|

Weight

|

|

|

Shipping Weight & Dimensions

|

|

|

Application Notes

|

-

Always use the mixer on level & stable surface for best performance and maximum safety

-

Do not use the mixer in a hazardous atmosphere, or with flammable, explosive, corrosive, poisonous material! Check the chemical resistanceof the container with the different material before loading the sample!!!

-

Do not overload the mixer! Stop the mixing operation immediately if abnormal sound/vibration are observed

-

Use a digital balance to make sure the sample loading is balanced before mixing

-

Double check if the containers are mounted correctly and securely before mixing

-

Do not open the cover lid until the rotation has completely stopped! Do not retrieve the containers and/or put hand close to mixing fixture while the rotation has not completely stopped!

-

Only use the included containers for the mixing operation! Double check to make sure there is no foreign object in the mixer before mixing

-

Please click underline to learn Centrifugal Force calculation.

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Pic. 1

Pic. 1  Pic.2

Pic.2  Pic. 3

Pic. 3  Pic. 4

Pic. 4