Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Item No.:

TMAX-Auto-CY-01Payment:

L/C, T/T, Western Union, Credit Cards, PaypalProduct origin:

ChinaShipping port:

Xiamen PortLead Time:

5 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

Introduction:

Tmax is a lithium-ion battery One Stop Solutions Provider, we can provide the Electrode Preparation-Cell Assembling-Final Cell Finishing whole process.

Cylindrical Battery Process Chart:

Cylindrical Cell Drawing Information required for designing the battery formula.

1. General information on target cell technology

|

Dimension |

Unit |

Cell Design |

|

Chemistry |

|

|

|

Capacity |

Ah |

|

|

Nominal Voltage |

V |

|

|

Cell format |

|

|

|

Cell weight |

g |

|

|

Target capacity per year(net) |

Gwh |

|

|

Target OEE |

% |

|

|

Shift per day |

# |

|

|

Hours per shift |

h |

|

|

Working days per year |

d |

2.Further information on cell technologies

Housing

Jelly Roll

Electrode Spec

Electrolyte

Anode Slurry

Cathode Slurry

Formation & aging protocol

EOL

Final grading

3.Cell drawings

Machinery List:

|

S NO. |

Workshop |

Equipment Name |

|

1 |

Cathode |

Oven |

|

2 |

Planetary Vacuum Mixer |

|

|

3 |

Turnover Barrel with lifting system |

|

|

4 |

Viscometer |

|

|

5 |

Coating Machine |

|

|

6 |

Thickness Gauge |

|

|

7 |

Continue Pressing Machine |

|

|

8 |

Auto Slitting Machine |

|

|

9 |

Baking Oven |

|

|

10 |

Anode |

Deionized water machine |

|

11 |

Planetary Vacuum Mixer |

|

|

12 |

Turnover Barrel with lifting system |

|

|

13 |

Viscometer |

|

|

14 |

Coating Machine |

|

|

15 |

Thickness Gauge |

|

|

16 |

Continue Pressing Machine |

|

|

17 |

Auto Slitting Machine |

|

|

18 |

Baking Oven |

|

|

19 |

Assemble |

Auto Winding Machine |

|

20 |

Short Testing Machine |

|

|

21 |

Bottom Shell Welding Machine |

|

|

22 |

Auto Grooving Machine |

|

|

23 |

Baking Oven |

|

|

24 |

Filling and |

Glove Box |

|

25 |

Laser Welder |

|

|

26 |

Linear Sealing Machine |

|

|

27 |

Battery Cleaning Machine |

|

|

28 |

PVC Shrinkage Machine |

|

|

29 |

Cartoning machine |

|

|

30 |

Grading |

Formation Machine |

|

31 |

Computer |

|

|

32 |

High temperature storage |

|

|

33 |

Normal temperature storage |

|

|

34 |

Cell Inkjet Printer |

|

|

35 |

OCV1 |

|

|

36 |

OCV2 |

|

|

37 |

OCV3(Sorting machine) |

|

|

38 |

Grading Machine |

|

|

39 |

Sorting machine |

|

|

40 |

Other |

NMP recovery system |

|

41 |

Plant dehumidification system |

|

|

42 |

Purified water |

|

|

43 |

Other Necessary |

Vacuum Pump + Compressed Air |

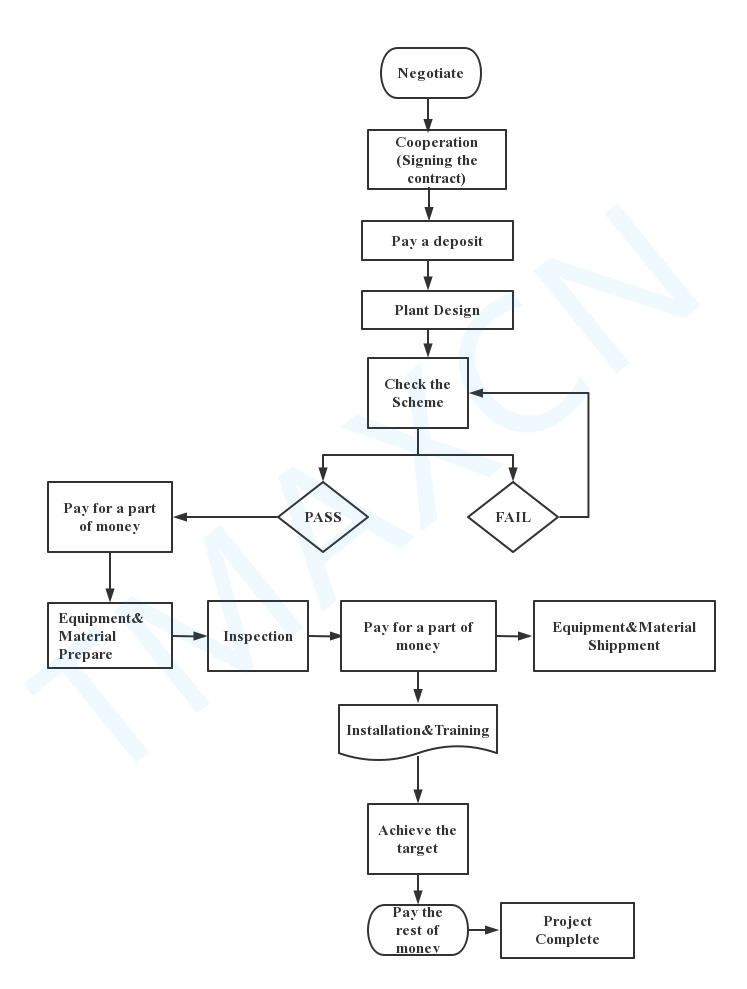

Project Implementation Process:

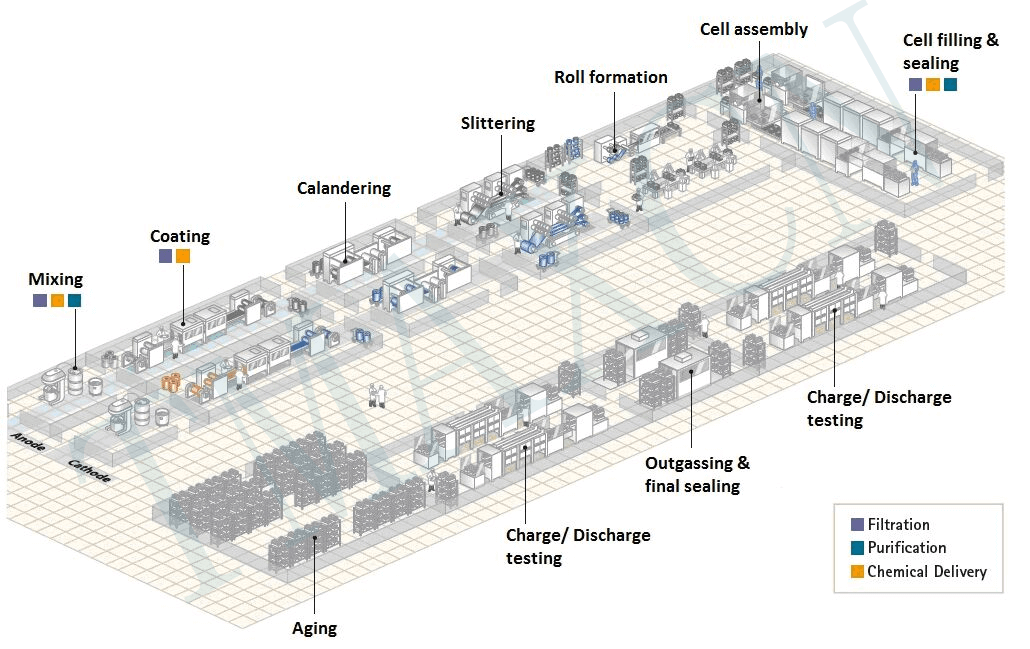

Battery Production Workshop:

Layout Reference

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

Battery Electrode Intermittent or Continuous Coating Machine For Production LineNext :

30L Planetary Vacuum Mixing Machine for Battery Slurry PreparationCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported