Join TMAX, become an agent!

Join TMAX, become an agent!

Sales Manager: Gia

Email: Gia@tmaxlaboratory.com

Wechat: Dingqiuna

Item No.:

TMAX-RBM-1500Payment:

L/C, T/T, Western Union, Credit Cards, PaypalShipping port:

Xiamen PortLead Time:

20 DaysCertificate:

CE, IOS, ROHS, SGS, UL CertificateWarranty:

Two years limited warranty with lifetime technical support

A. Working principle and use:

The grinding medium and materials in the tank of the light roller ball mill are lifted to a certain height with the rotation of the cylinder, and are separated from the cylinder wall along the parabola due to the action of gravity. Under the impact, rolling and sliding of the grinding medium, the materials produce high-energy impact, shear and rolling to achieve the process purposes of grinding, grinding, dispersion, mixing, alloying and sphericity.

Light roller ball mill is a medium batch, mass production of ultrafine grinding equipment, widely used in electronic materials, magnetic materials, ceramic glaze, metal powder, non-gold ore, new materials and other industries.

B. Technical parameter

|

Model number |

RBM-1500 |

|

Ball mill tank volume (ML) |

1500L |

|

Effective volume of ball milling |

About 500L |

|

Material and size of ball mill tank |

Stainless steel tank |

|

Ball mill medium |

Stainless steel ball |

|

Maximum loading per tank |

The material and grinding medium shall not exceed two-thirds of the volume |

|

Rotational speed |

20-34r/min(±2) |

|

Speed regulation mode |

Variable frequency speed regulation |

|

Outlet distance from ground (MM) |

Vibrating machine height (discharge port connected to vibrating machine) |

|

Feeding inlet size and others |

Production according to customer requirements, convenient loading, discharging |

|

Loading method |

Screw feed |

|

Discharge method |

Screen and pneumatic butterfly valve integrated, automatically start the butterfly valve can be discharged. |

|

Operating voltage |

Three-phase 380V, 50HZ |

|

Main motor power and inverter power |

15KW (motor brand is Dedong, inverter brand is Delixi) |

|

Equipment reference size (MM) |

3500(L) *1890 (W) *3600 (H) including feeding machine |

|

Equipment reference weight (KG) |

About 2600 |

C. Product features:

1, Equipment stable operation, low power consumption, suitable for customer material fineness requirements are not high, medium batch, mass production;

2, Can be dry, wet grinding, mixing, alloying, spherical and other processes, can deal with various hardness of materials;

3, The biggest advantage of the equipment is that it can carry out automatic discharge and automatic separation of ball material, suitable for mass production, automatic positioning feeding and discharging system can be selected;

4, According to the different characteristics of customer materials, the ball mill can be lined with different materials, such as zirconia, alumina, polyurethane, nylon, tetrafluoride, cemented carbide, etc., to ensure that the material is not polluted, high purity;

5, Can be customized according to the special needs of customers;

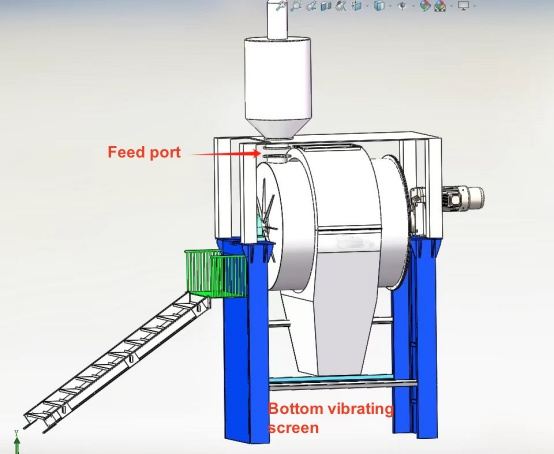

D. Light roller ball mill related pictures

E. The operation process of the whole machine

a. The vacuum feeder automatically feeds the storage barrel, the storage barrel volume is 400L, the ball mill material is 330L when it is full, and the feeding will stop when it is full.

b. Manually go to the feeding platform to remove the feed plug of the ball mill, connect the soft connected flange of the storage barrel with the flange of the ball mill tank, start the button and open the pneumatic butterfly valve at the bottom of the discharge barrel, and the exhaust valve opposite the feed port will automatically open accordingly to start the feed. (A pneumatic hammer or rotary valve can be added to the side wall of the storage barrel according to the flow of the material, and the ball grinding tank can be controlled by the program, which can swing back and forth at a small angle to avoid material accumulation and blocking the feed port)

c. After the storage barrel is finished with the materials, manually remove the storage barrel flange and install the plug on the ball mill barrel. After the personnel evacuate to the operating platform, start the equipment and start the ball mill. When starting the equipment, close the valve of the storage barrel and the exhaust valve of the ball mill tank accordingly. Vacuum feeder restarts feeding. (The loading operation platform is equipped with the corresponding photoelectric induction switch, the loading hose is not detached, the personnel is not evacuated, and the equipment cannot be started)

d. After the ball grinding is completed, start the discharge procedure, and automatically open the pneumatic butterfly valve of the discharge port after the discharge port faces up, and begin to rotate out of the shock screen machine at low speed. The shock screen machine is soft connected with the discharge cover flange, and the shock screen machine has a coarse powder discharge and a fine powder outlet.

e. After the discharge is completed, the discharge port and the feed port face up automatically. The discharge port is provided with a butterfly valve dust blowing device, which automatically closes after the butterfly valve is blown. Manual loading on the loading platform.

f. The whole operation is controlled by the PLC touch screen program

F. Introduction of vibrating screen

Model: JT-ZS600

|

No. |

Name |

Material |

Material type |

Remark |

|

1 |

Dust cover |

SUS304 |

1.2mm |

|

|

2 |

Frame |

SUS304 |

2.0mm |

|

|

3 |

Engine base |

A3 |

4.0mm |

|

|

4 |

Oscillating body |

A3 |

6.0-16mm |

|

|

5 |

Electric machine |

Fully enclosed, oil-free, maintenance-free, copper wire package |

0.55Kw |

|

|

6 |

Large diffraction aperture |

SUS304 |

2.5mm |

|

|

7 |

Small diffraction aperture |

SUS304 |

2.5mm |

|

|

8 |

Net frame |

SUS304 |

2.5mm |

|

|

9 |

Screen |

SUS304 |

40 mesh |

|

|

10 |

Punched plate |

SUS304 |

1.5 mm |

|

|

11 |

Bottom cylinder flange |

A3 |

6.0 mm |

|

|

12 |

Screen diameter |

SUS304 |

Diameter 600 |

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Previous :

High Efficiency Ultra-Fine Grinding And Mixing Liner Roll Ball Mill MachineNext :

12 Working Stations 3 Layers Jar Grinding Ball Mill MachineCategories

© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported