Punch Press Dies: Essential Tools in Metal Forming

● Introduction

Punch press dies are critical components in metal forming processes, enabling the cutting, shaping, and bending of metal sheets with precision and efficiency. These dies are used in conjunction with punch presses, which apply force to the dies to perform various operations on the metal. This article delves into the types, design, materials, manufacturing, and applications of punch press dies, highlighting their significance in modern manufacturing.

● Types of Punch Press Dies

1. **Blanking Dies**:

- Used to cut out flat pieces of material, known as blanks, from larger metal sheets. The blank is the desired part, and the remaining material is scrap.

2. **Piercing Dies**:

- Designed to punch holes in the metal sheet. The material removed from the sheet is the scrap, and the sheet with holes is the desired part.

3. **Bending Dies**:

- Used to bend the metal sheet at specific angles. Types include V-dies, U-dies, and wiping dies, each providing different bending profiles.

4. **Forming Dies**:

- Shape the metal sheet into complex three-dimensional forms. These dies are used in deep drawing and other forming processes.

5. **Compound Dies**:

- Combine two or more operations in a single stroke of the press, such as blanking and piercing simultaneously, to improve efficiency.

6. **Progressive Dies**:

- Feature multiple stations, each performing a different operation. As the sheet metal advances through the die, it undergoes a series of operations to produce the final part.

7. **Transfer Dies**:

- Move the part from one station to another within the same die set or between different die sets, allowing for complex multi-step operations.

● Design of Punch Press Dies

1. **Die Components**:

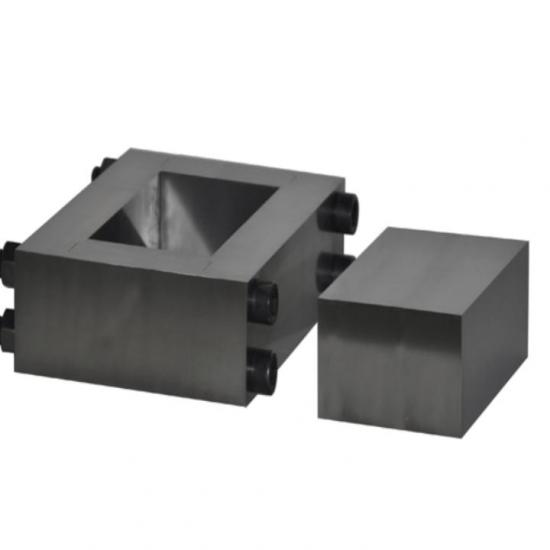

- **Die Block**: The main body of the die that houses the cutting or forming sections.

- **Punch**: The part of the die that applies force to the material to perform the cutting or shaping operation.

- **Strippers**: Hold the material in place and remove it from the punch after the operation.

- **Pilots**: Ensure precise alignment of the material as it moves through the die.

- **Shanks**: Attach the punch to the press.

2. **Die Design Considerations**:

- **Material Type**: The type of metal being processed affects the design, including the die material and geometry.

- **Thickness and Tolerances**: The thickness of the metal sheet and the required tolerances determine the die's strength and precision.

- **Production Volume**: High-volume production requires durable dies made from high-quality materials.

- **Complexity of the Part**: More complex parts require sophisticated die designs with multiple stages.

● Materials Used

1. **Tool Steels**:

- High-carbon and high-chromium tool steels are commonly used for their hardness, wear resistance, and ability to retain a sharp cutting edge.

2. **Carbides**:

- Tungsten carbide is used for high-wear applications due to its exceptional hardness and durability.

3. **Alloys**:

- Various alloy steels provide a balance between toughness and wear resistance, suitable for different applications.

4. **Surface Treatments**:

- Surface treatments such as nitriding, carburizing, and coating with materials like titanium nitride (TiN) can enhance the performance and lifespan of the dies.

● Manufacturing of Punch Press Dies

1. **Design and CAD Modeling**:

- The design process starts with creating detailed CAD models, considering all operational requirements and tolerances.

2. **Machining**:

- CNC machining, EDM (Electrical Discharge Machining), and grinding are used to manufacture the die components with high precision.

3. **Heat Treatment**:

- Heat treatment processes such as quenching and tempering increase the hardness and strength of the die components.

4. **Assembly and Testing**:

- The components are assembled, and the dies are tested to ensure they meet the required specifications and perform accurately in production.

● Applications

1. **Automotive Industry**:

- Punch press dies are used to produce a wide range of automotive parts, including body panels, brackets, and engine components.

2. **Electronics**:

- Precision dies are essential for manufacturing components like connectors, housings, and metal frames in the electronics industry.

3. **Aerospace**:

- High-performance dies are used to form lightweight, high-strength components for aircraft and spacecraft.

4. **Consumer Goods**:

- Dies are used to produce various consumer products, from kitchen appliances to metal furniture parts.

5. **Construction**:

- Structural components, fixtures, and fittings for the construction industry are often produced using punch press dies.

● Conclusion

Punch press dies are indispensable tools in modern manufacturing, enabling the efficient and precise shaping of metal sheets into a vast array of products. Their design, material selection, and manufacturing processes are critical to ensuring high-quality production and longevity. As technology advances, the development of more sophisticated dies continues to drive innovation and efficiency in various industries, making punch press dies a cornerstone of industrial manufacturing.