Join TMAX, become an agent!

Join TMAX, become an agent!

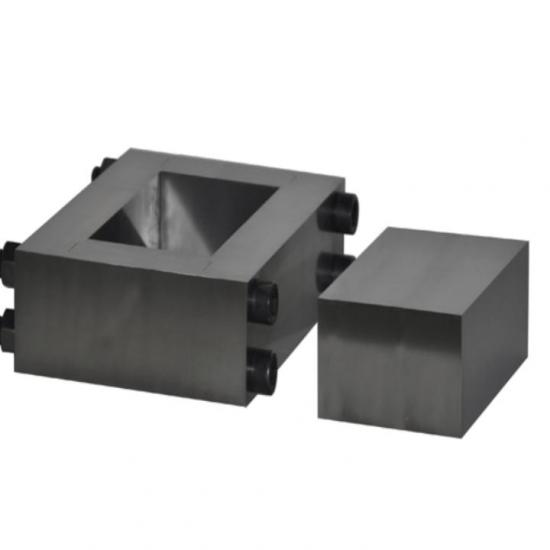

Hydraulic Press Molds

Previous :

Cold Isostatic PressingNext :

Powder Tablet Press© Copyright: 2025 Xiamen Tmax Battery Equipments Limited All Rights Reserved.

IPv6 network supported